Mission Operations

The Space Telescope Operations Control Center at NASA’s Goddard Space Flight Center in Greenbelt, Maryland is the engine that keeps Hubble operating 365 days a year, 24 hours a day.

Quick Facts

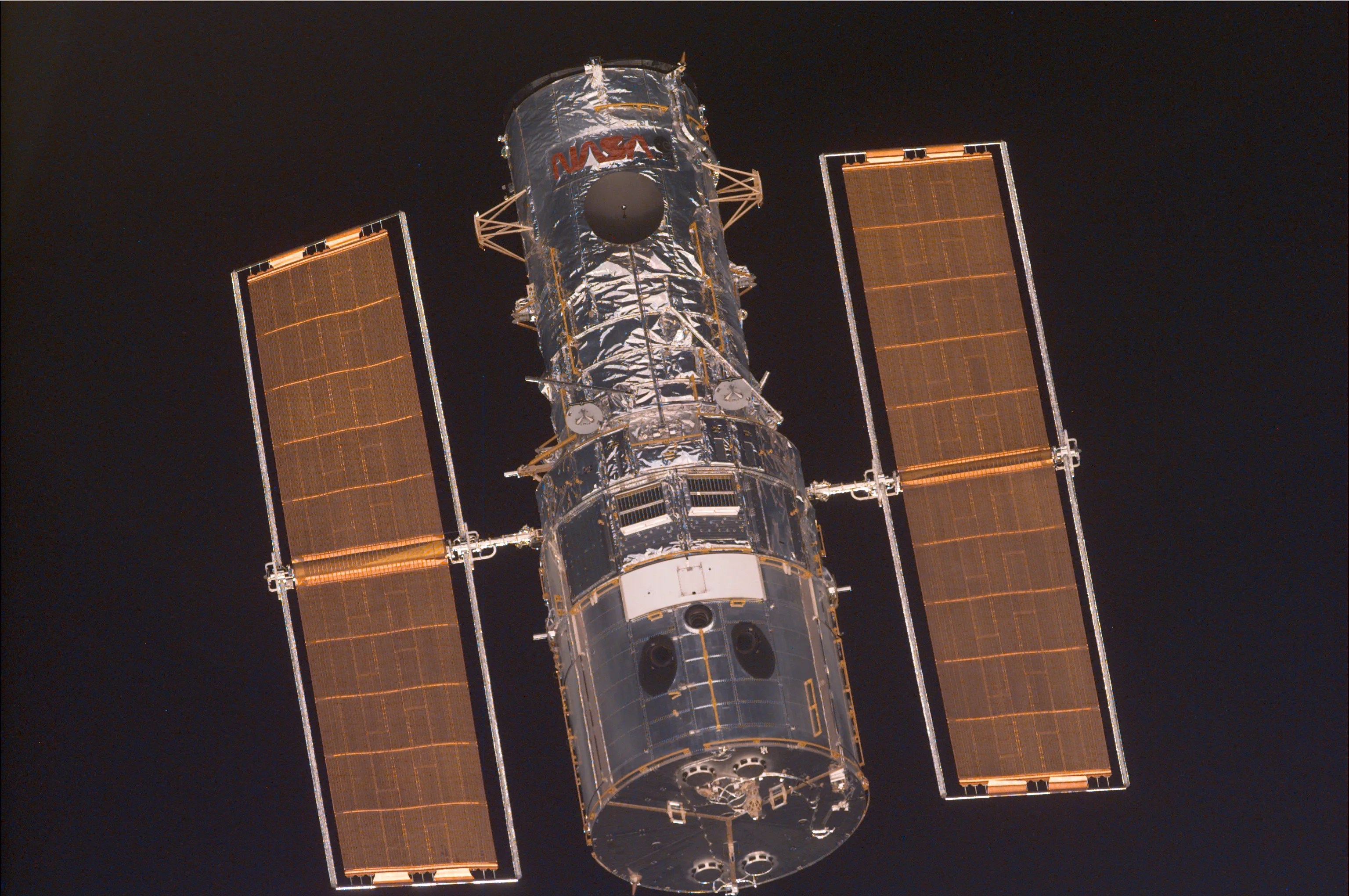

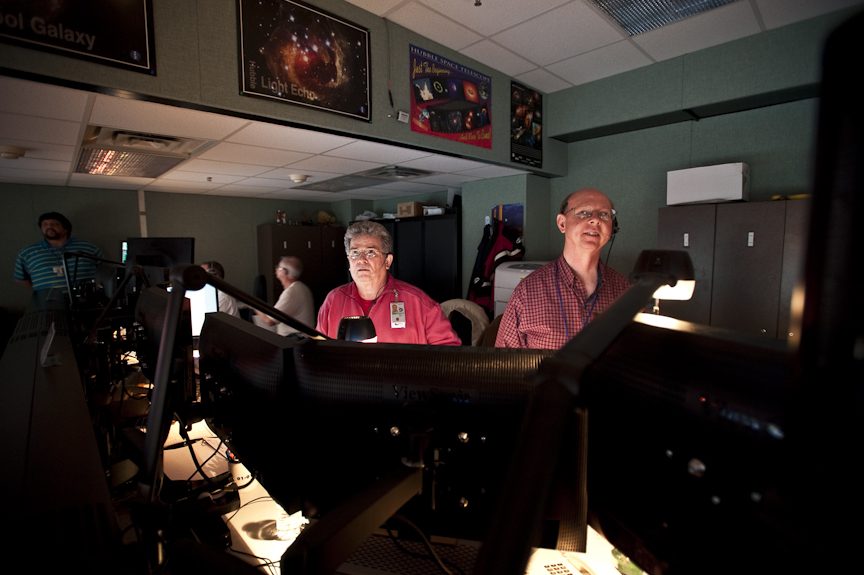

Behind Hubble’s captivating images and groundbreaking science is a team of people who control the telescope, ensure its health and safety, and innovate ways to keep it at top performance more than three decades after its launch. This group of engineers, scientists, and operators at NASA’s Goddard Space Flight Center work together to monitor Hubble as it travels around Earth, point the telescope at cosmic targets, and solve any problems that arise. They perform their work in specialized facilities that provide the tools and equipment needed to operate this great observatory and continue its legacy of success.

Control Center

NASA’s Goddard Space Flight Center is home to the Hubble Space Telescope Operations Project, the agency’s team of managers, engineers, and scientists who oversee all aspects of the Hubble mission. The mission operations team is an integrated group of civil servants and contractors who are responsible for Hubble’s day-to-day activities – those functions of the mission that assure the health, safety, and performance of the spacecraft. Examples of the work performed by the operations team include commanding the spacecraft, monitoring and adjusting the spacecraft’s systems (power, thermal, data management, pointing control, etc.), developing flight software, upgrading the control center’s hardware and software, and maintaining the network and ground systems. Many of these activities are performed in the Space Telescope Operations Control Center (STOCC), the nerve center for Hubble’s mission operations.

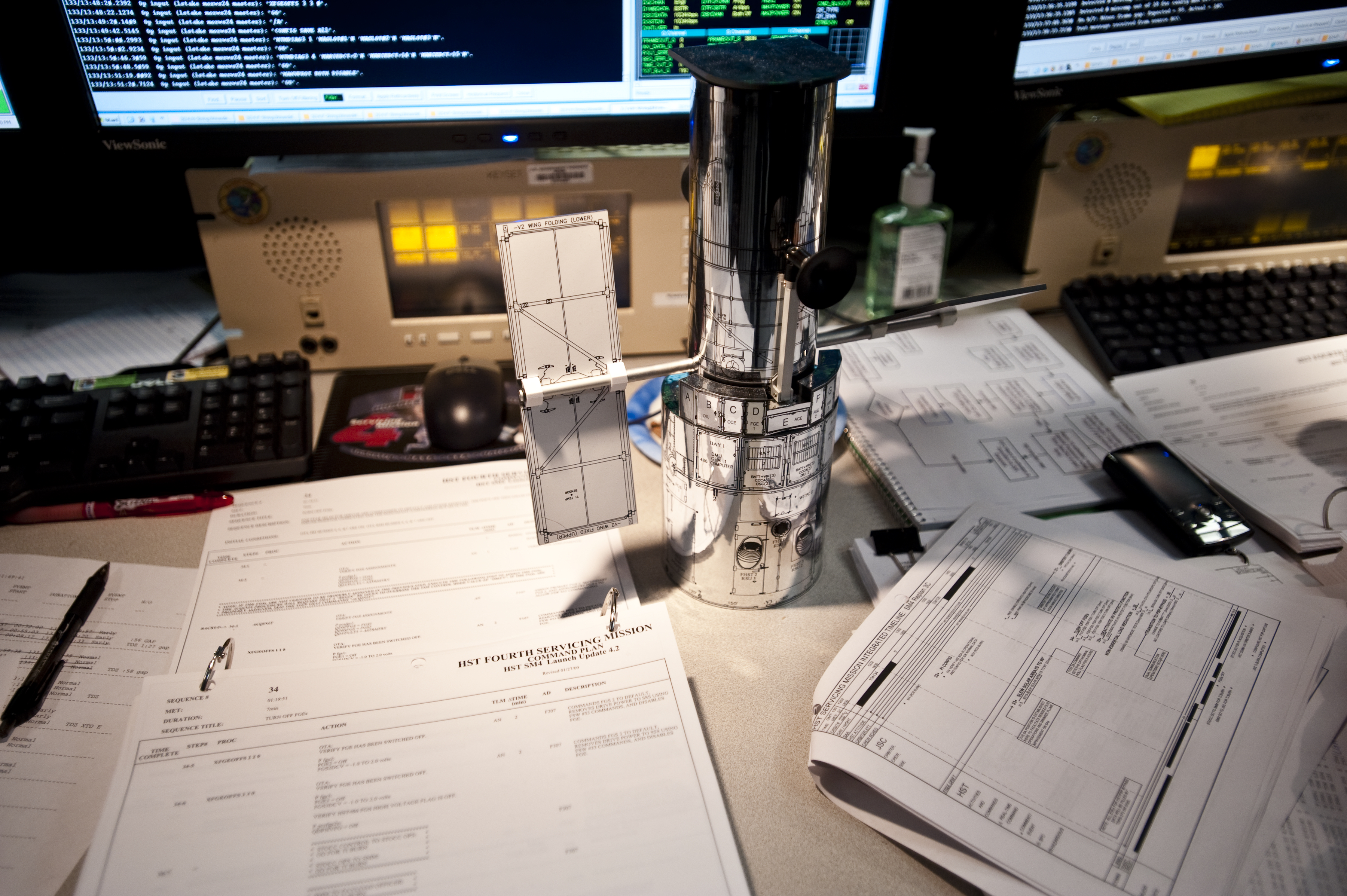

The STOCC consists of a Mission Operations Room (MOR) and an Operations Support Room (OSR). The MOR is Hubble’s primary command and control room; both manual and automated operations are performed from this location.

Prior to the implementation of automated operations in May 2011, a team of console operators staffed the MOR around the clock. They executed the required procedures to acquire communications with the telescope, managed Hubble’s science and engineering data recorders, and loaded Hubble’s computers with command sequences. They also monitored telemetry from the spacecraft and reported any problems or concerns to the appropriate subsystem engineers.

These functions, which form Hubble’s daily routine, are now performed autonomously, enabling STOCC personnel to focus on special operations and various tests. Since the advent of automated operations, the STOCC is staffed only eight hours a day, five days a week. If an anomaly occurs on the spacecraft or within the ground system when the facility is unoccupied, a high-reliability text messaging system immediately alerts the appropriate members of the operations team.

In the Operations Support Room (OSR), STOCC personnel work with a high-fidelity spacecraft simulator, or directly with the spacecraft, to conduct a variety of tasks. These include testing any configuration changes planned for Hubble, analyzing engineering telemetry, testing flight or ground software updates, and monitoring any contingency procedures or other special commanding in response to an observatory anomaly. The operations team continuously examines spacecraft subsystem performance, looking for trends that could signal component degradation and identifying ways to improve system performance and extend the mission’s lifetime.

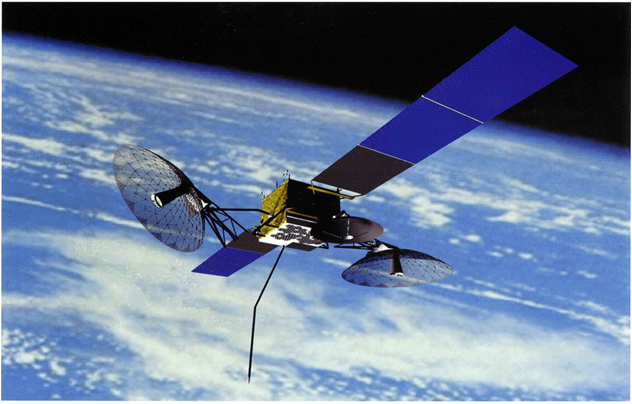

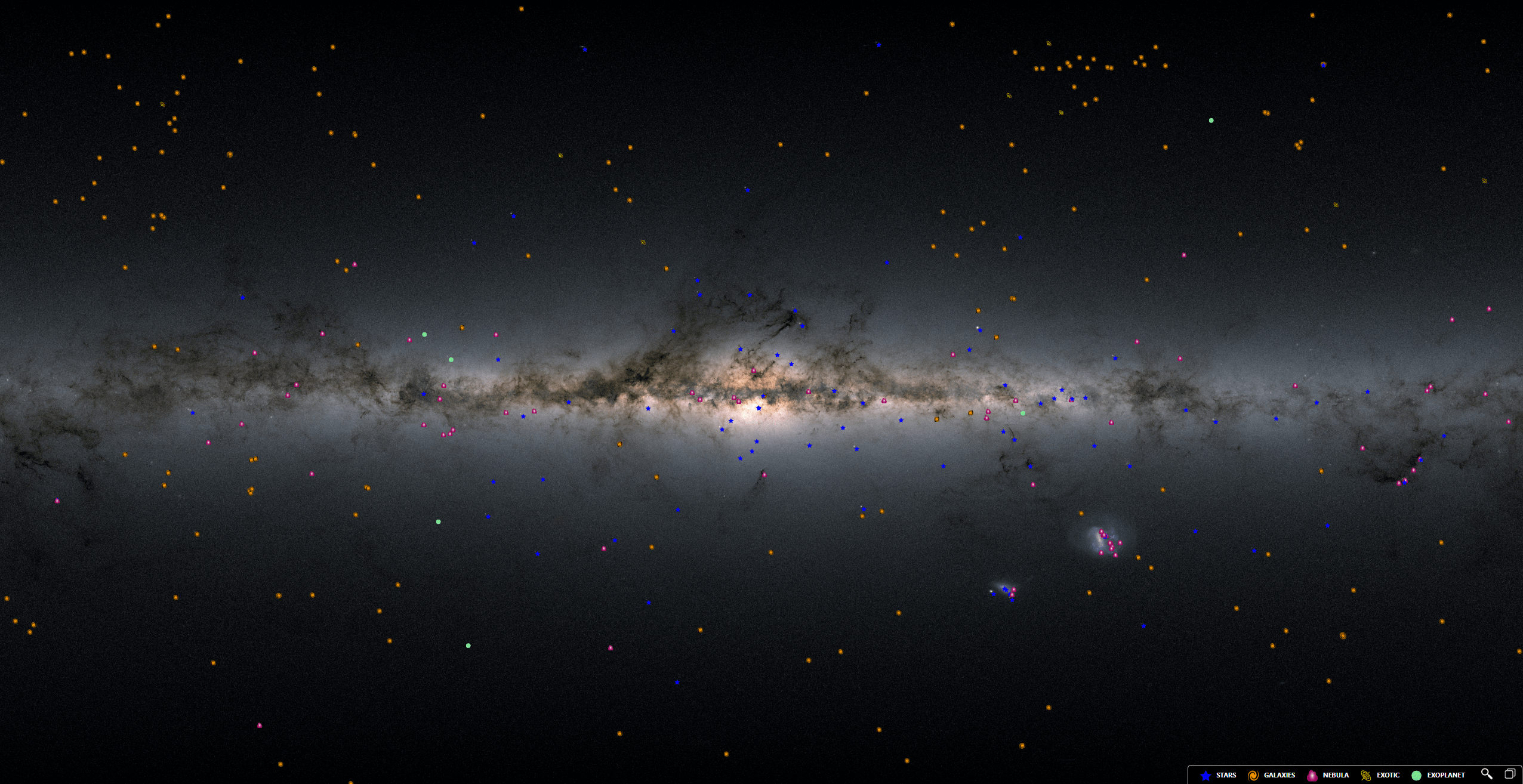

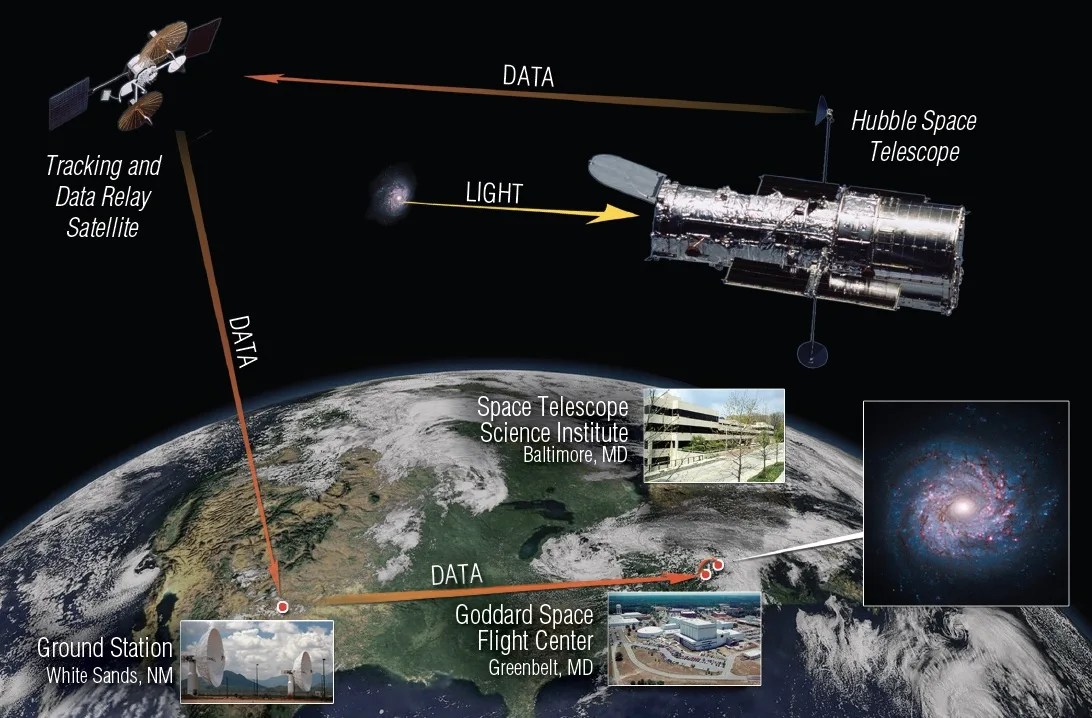

Communications with Hubble are accomplished via a network interface from the STOCC to NASA’s White Sands Test Facility complex located in White Sands, New Mexico, near Las Cruces. The large antennas there transmit radio waves to NASA’s Tracking and Data Relay Satellite System (TDRSS), which forwards them to Hubble. Science observations and engineering data that the telescope stores on solid-state recorders are returned to Goddard using the reverse path. Once received and quality checked, the science data is forwarded to the Space Telescope Science Institute via dedicated high-speed network links where it is processed, archived, and distributed.

The Hubble mission and science operations teams strive to set the standard for NASA’s great observatories by continuously improving the telescope’s science productivity. The optical quality of the telescope, the excellent pointing performance of the spacecraft, the diverse capabilities of its instruments, and the skillful dedication of the mission’s staff keep Hubble at the forefront of observational astrophysics. The observatory is operating at peak performance thanks to the astronauts who successfully completed Servicing Mission 4 in May 2009. During that mission, astronauts installed two advanced-technology instruments; repaired two others; replaced a Fine Guidance Sensor, six gyros, six batteries, and the instrument computer; and outfitted certain equipment bays with protective thermal blankets. These upgrades positioned Hubble to continue its mission of discovery for years to come.

Featured Video Series:

Hubble Mission Operations

Hubble Eye in the Sky

For more than three decades, Hubble has surpassed scientific expectations and more than doubled its predicted lifespan. This three-part miniseries goes behind the scenes of Hubble's Mission Operations. Meet the people who keep NASA's Eye in the Sky going, and discover the intricacies of keeping a 30+-year-old telescope operating in the harsh environment of space!

Mission Operations 360° Tour

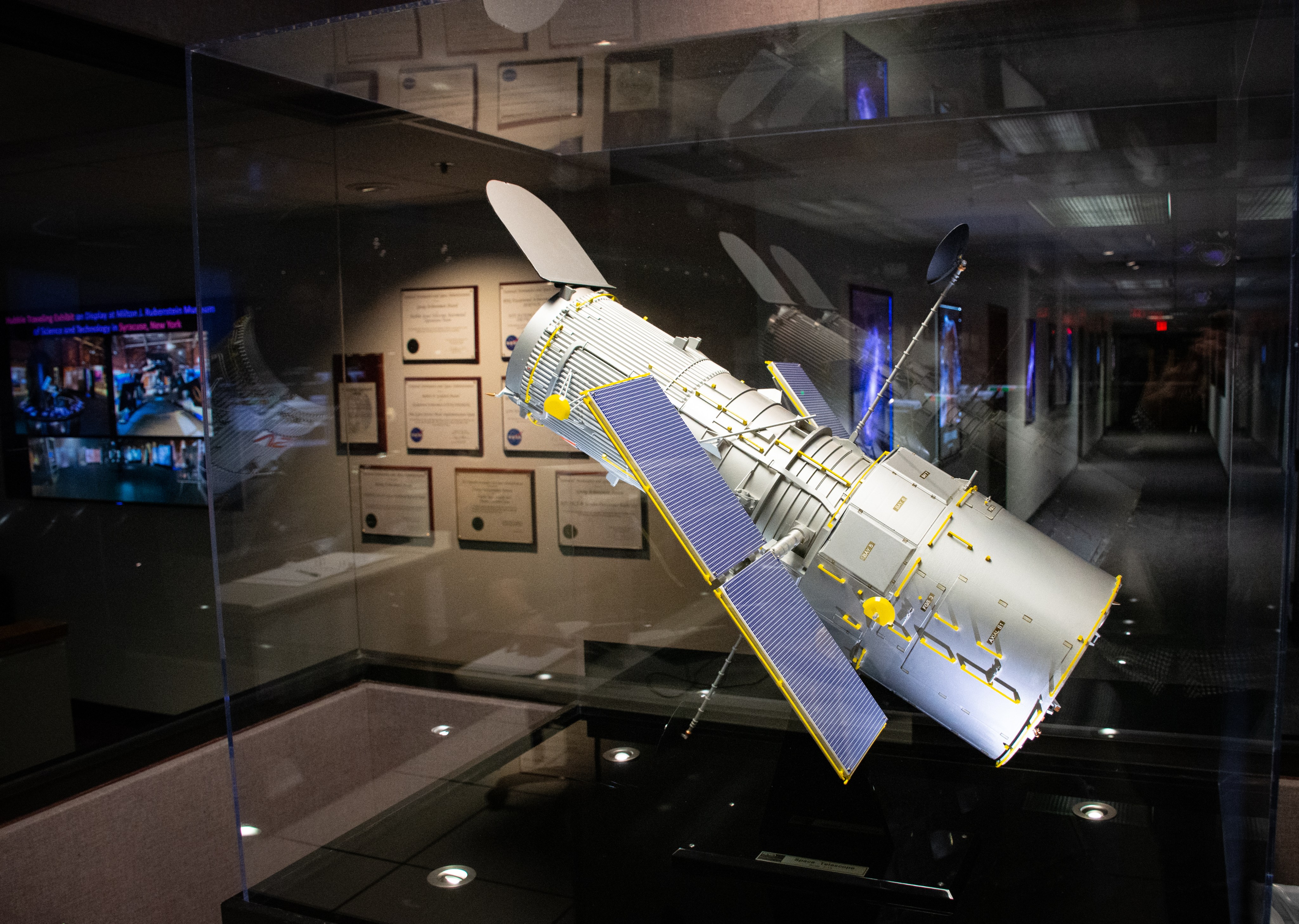

Take a 360°, virtual tour of the Hubble Space Telescope’s home for mission operations, the Space Telescope Operations Control Center (STOCC) at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. Begin in the lobby to learn about the orbiting spacecraft. Visit the Mission Operations Room, where the flight operators command and monitor Hubble. Step into the Operations Support Room, where the flight team investigates spacecraft anomalies and verifies new procedures. Then explore the exhibit hallway to view hardware that once flew in space aboard Hubble as well as tools that astronauts used to repair and upgrade the observatory.

(To watch 360° videos, you need the latest version of Chrome, Opera, Firefox, or MS Edge on your computer. On mobile devices, use the latest version of the YouTube app.)

NASA's Goddard Space Flight Center

Simulator

The Vehicle Electrical System Test (VEST) facility provides Hubble operations and engineering personnel with a configurable, high-fidelity simulator of the Hubble observatory and its operating environment.

The VEST is used in three primary ways. First, it is employed to troubleshoot problems seen on the spacecraft by simulating the conditions under which the anomaly was observed and to test possible solutions. Second, it is used to verify updates to the software, commands and engineering parameters before they are transmitted from the control center to the spacecraft. This process includes a thorough test of the ground procedures used for uplinking and installing these items. Finally, the VEST is used to verify operational procedures before they are executed by the flight operations team.

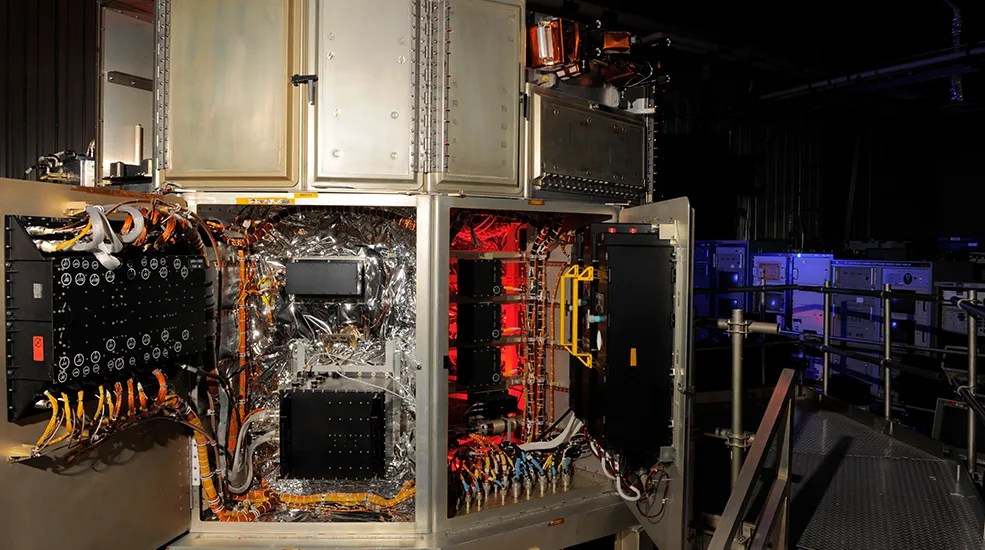

The VEST consists of several distinct elements. The largest is the integrated VEST structure itself. This is a mechanical and electrical engineering model of Hubble’s middle section (known as the Support Systems Module and the Optical Telescope Assembly Equipment Section) that contains the majority of the spacecraft’s hardware subsystems. Mounted within the structure are spaceflight-qualified modules developed as spares for servicing Hubble in orbit, and engineering duplicates (where no spares exist) of such items as computers, data recorders, interface boxes, power control units, etc.

A second element includes specially fabricated units designed to mimic the functionality of subsystems on Hubble that are too big or require emulation of the space environment. One such area is the spacecraft’s electrical power subsystem, which includes its two solar arrays, drive mechanisms (used to turn the arrays toward the Sun) and six large batteries. Another area is the attitude guidance system that controls Hubble’s pointing and the observatory’s motion from target to target. In this area are units that simulate Hubble’s four 100-pound (45-kg) reaction wheels, six sensitive gyroscopes, sun sensors and other miscellaneous components.

A third element simulates Hubble’s complex science instruments – both cameras and spectrographs. In this case, large computer racks developed for each instrument known as instrument benches simulate the electronics portion of an instrument and its optical parts like filter wheels, calibration lamps and channel-select mechanisms. Additional imbedded components generate realistic science data used to conduct end-to-end dataflow tests of the larger system.

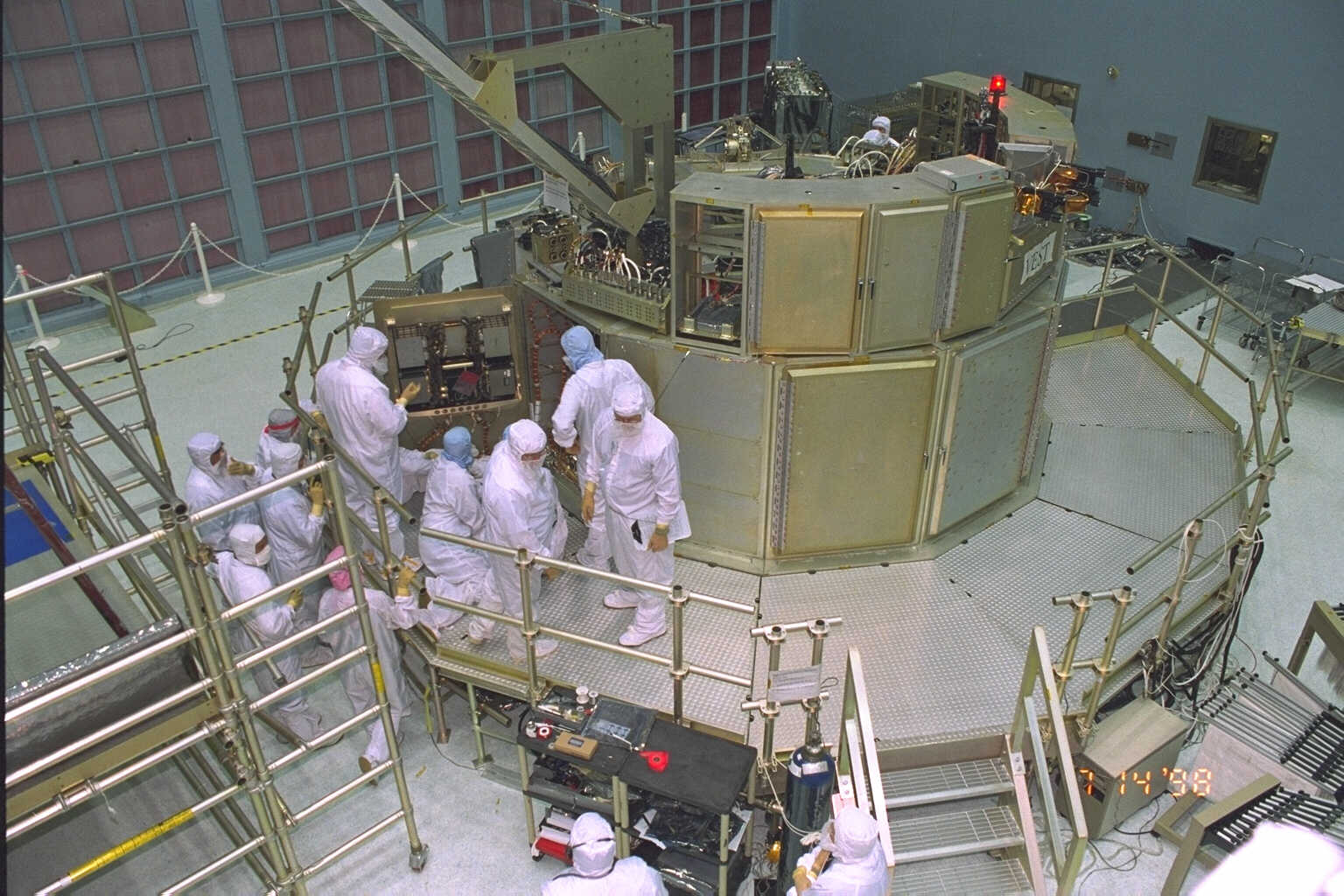

Prior to each of the five servicing missions to Hubble, the VEST structure was a critical element for ensuring the fit and function of new spaceflight hardware into the spacecraft. Many of the items taken aloft by the astronauts to Hubble were first installed into the VEST structure to verify mechanical, electrical and software compatibility with the observatory. During that time, the VEST structure was located inside a large clean room whose environment was vital to maintaining the pristine condition of the hardware, as even a speck of dust could have potentially contaminated Hubble’s sensitive instruments and subsystems.

Featured Video: Hubble's Clock Rollover

It's Time to Change Hubble's Clock

Remember that Y2K thing a few years ago? Well, it turns out Hubble has something similar, only Hubble’s clock restarts every 6,213 days, 18 hours, 48 minutes, and 31.875 seconds, or roughly every 17 years.