Overview

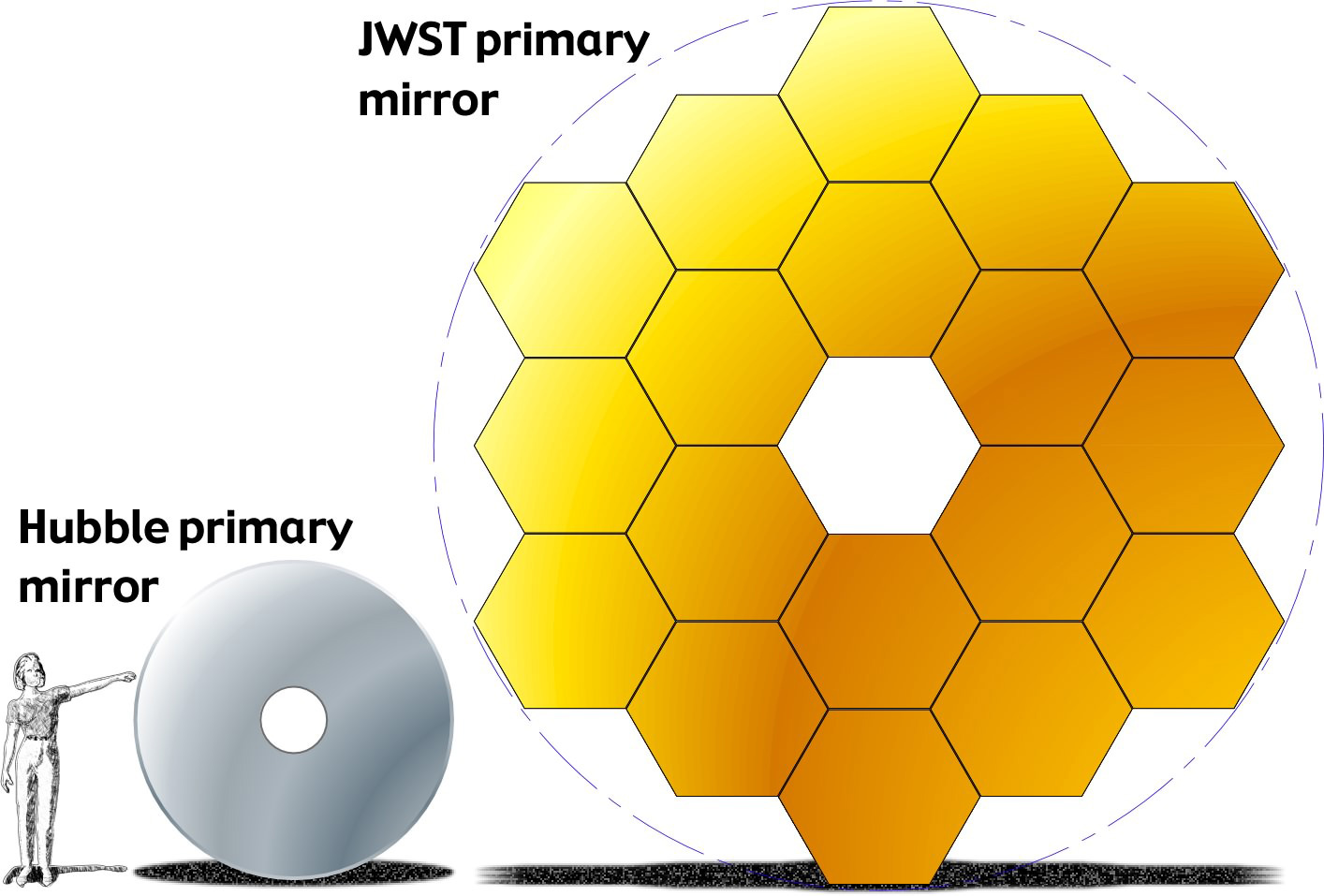

One of the James Webb Space Telescope's science goals is to look back through time to when galaxies were young. Webb does this by observing galaxies that are very distant, at over 13 billion light years away from us. To see such far-off and faint objects, Webb needs a large mirror. A telescope’s sensitivity, or how much detail it can see, is directly related to the size of the mirror area that collects light from the objects being observed. A larger area collects more light, just like a larger bucket collects more water in a rain shower than a small one.

Quick Facts

Video Overview

What Kind Of Telescope Is Webb?

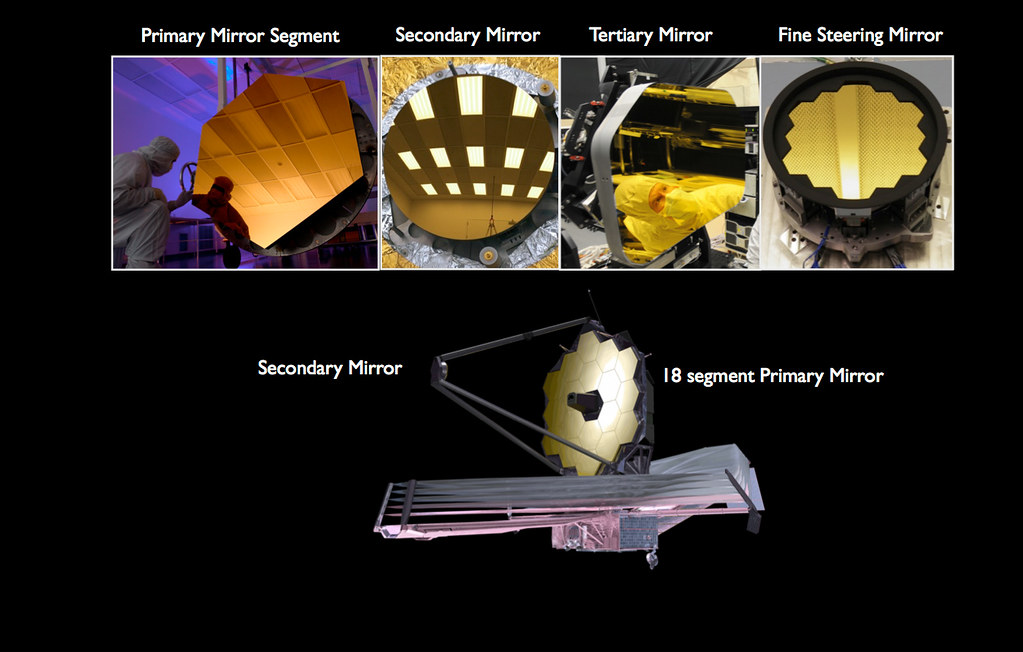

Webb is what is known as a three mirror anastigmat telescope. In this configuration, the primary mirror is concave, the secondary is convex, and it works slightly off-axis. The tertiary removes the resulting astigmatism and also flattens the focal plane. This also allows for a wider field of view.

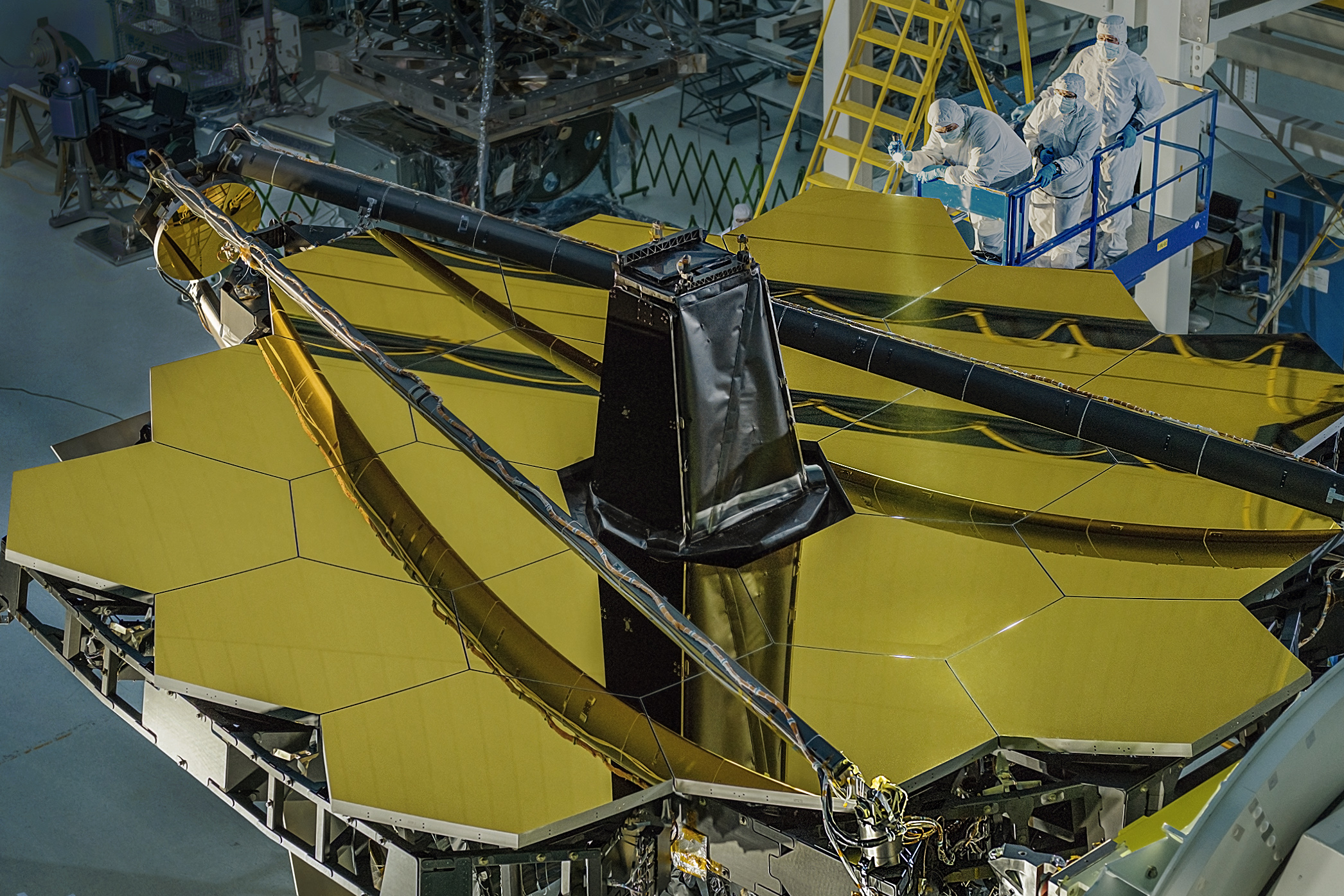

Webb's Four Mirrors

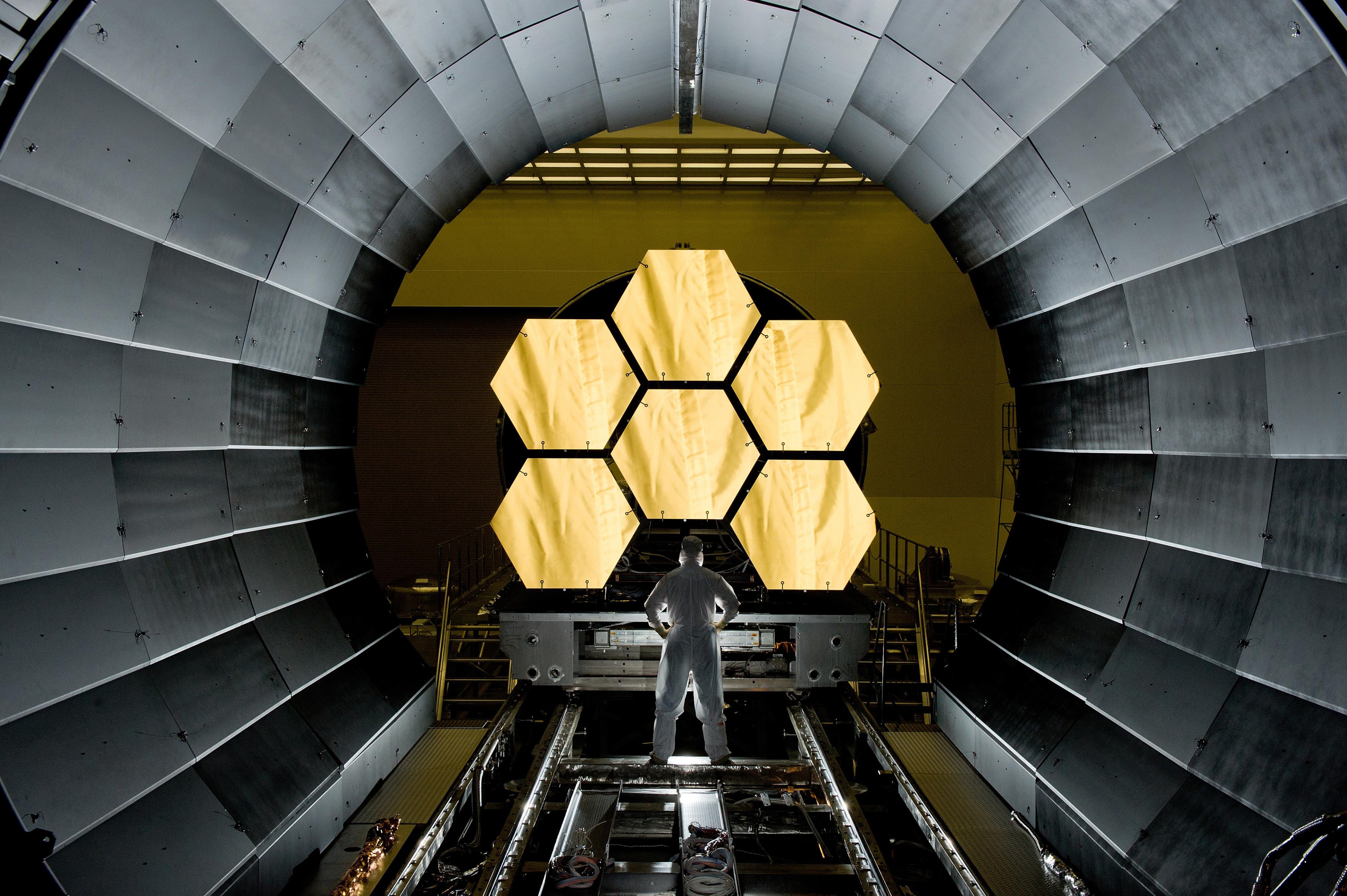

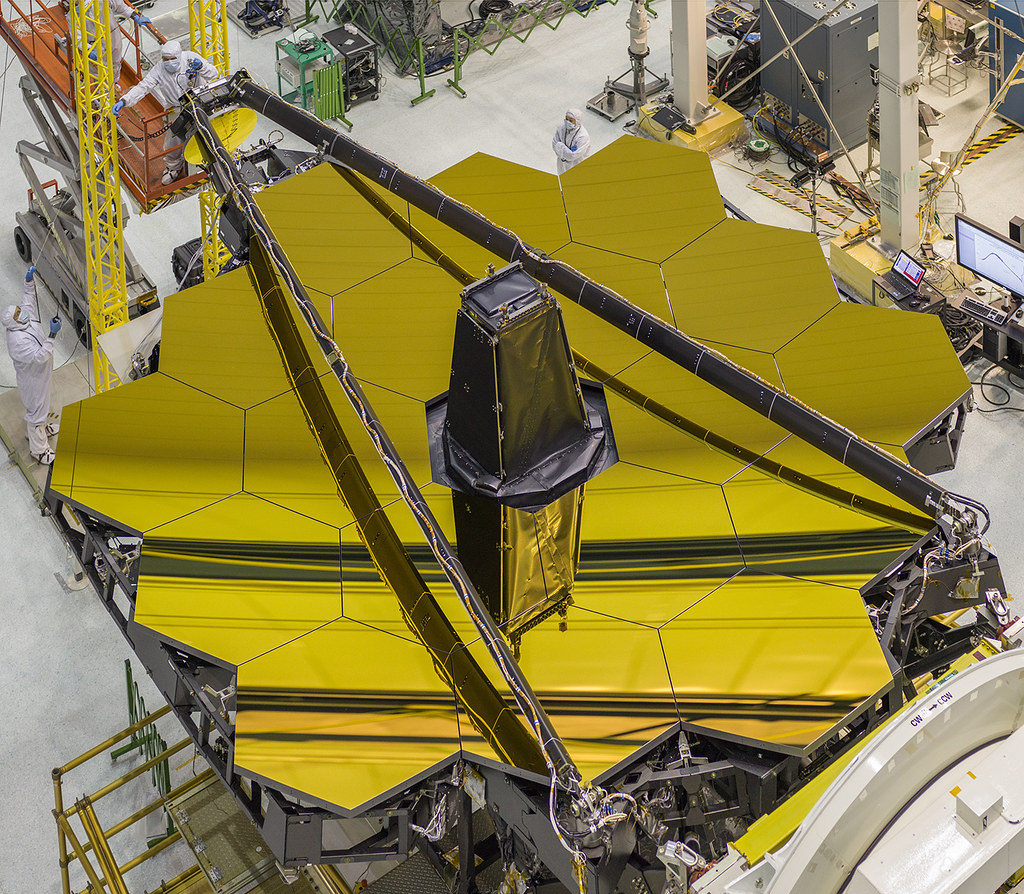

Webb is known for it's iconic hexagonally segemented golden primary mirror but there are 3 other mirrors in Webb's optics that all function together to bring light to Webb's instruments (see the overview video for an animation of this concept). The 18 hexagonal primary miror segements are precisely aligned to act as one large concave primary mirror which first gathers light and focuses it onto the round convex secondary mirror that lies at the end of Webb's long folding booms. The secondary mirror reflects the light back to the concave rectangular tertiery mirror which reflects it to the flat fine steering mirror from which light travels into Webb's instruments.

Story of Webb Image Gallery

This gallery has many great pictures of Webb mirrors and structures during their development and integration.

The image below is a SLIDESHOW. Hover over the image to see the image title and controls. Click the image to go to a detail page with more info and the ability to download the image at various resolutions (click downward arrow in lower right corner).

Engineering Challenges

Webb Telescope's scientists and engineers determined that a primary mirror 6.5 meters (21 feet 4 inches) across is what was needed to measure the light from these distant galaxies. Building a mirror this large was challenging, even for use on the ground. A mirror this large had never before been launched into space!

If the Hubble Space Telescope's 2.4 meter mirror were scaled to be large enough for Webb, it would be too heavy to launch into orbit. The Webb team had to find new ways to build the mirror so that it would be light enough - only one-tenth of the mass of Hubble's mirror per unit area - yet very strong.

The Webb Telescope team decided to make the mirror segments from beryllium, which is both strong and light. Each segment weighs approximately 20 kilograms (46 pounds).

Folding Mirrors

The Webb Telescope team also decided to build the mirror in segments on a structure which folds up, like the leaves of a drop-leaf table, so that it can fit into a rocket. The mirror would then unfold after launch. Each of the 18 hexagonal-shaped mirror segments is 1.32 meters (4.3 feet) in diameter, flat to flat. (Webb's secondary mirror is 0.74 meters in diameter.)

Why Hexagonal?

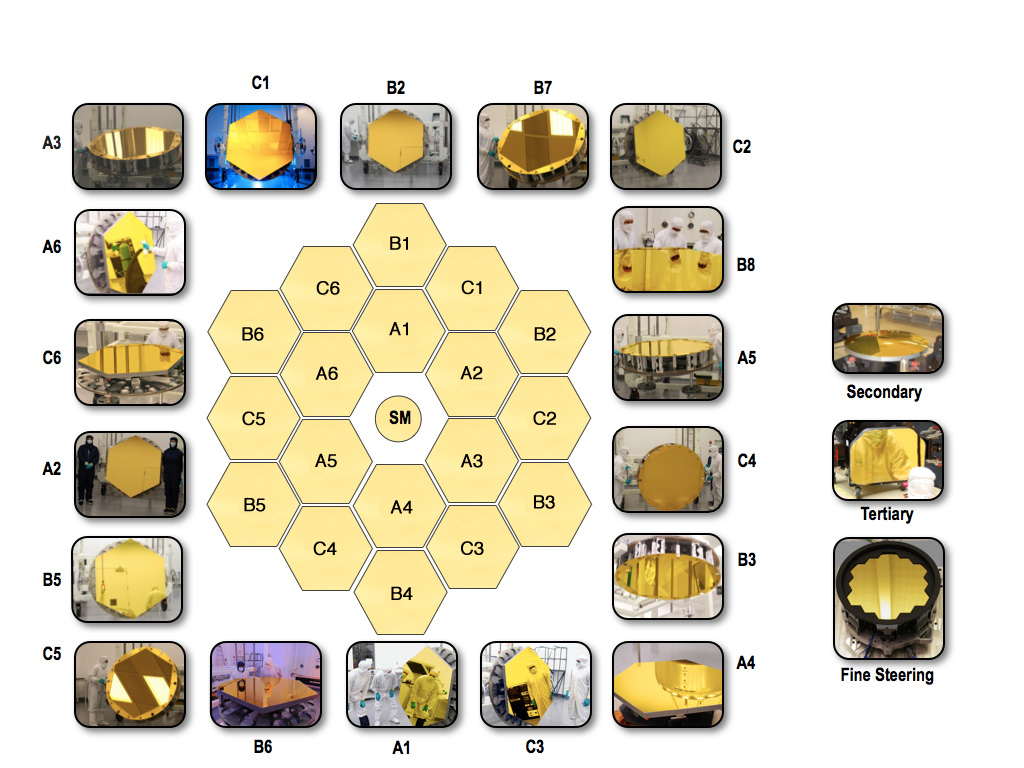

The hexagonal shape allows for a roughly circular, segmented mirror with "high filling factor and six-fold symmetry." High filling factor means the segments fit together without gaps. If the segments were circular, there would be gaps between them. Symmetry is good because there need only be 3 different optical prescriptions for 18 segments, 6 of each (see above right diagram). Finally, a roughly circular overall mirror shape is desired because that focuses the light into the most compact region on the detectors. A oval mirror, for example, would give images that are elongated in one direction. A square mirror would send a lot of the light out of the central region.

Achieving A Single Perfect Focus- Actuators

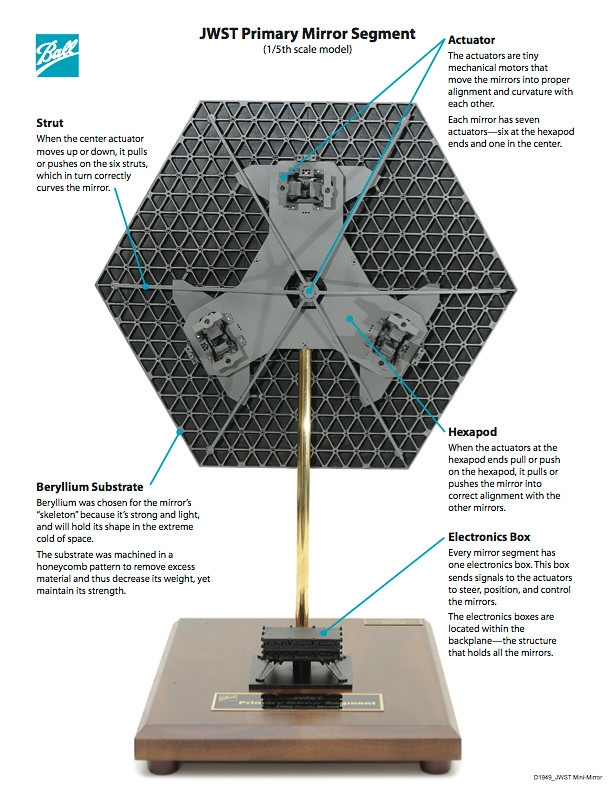

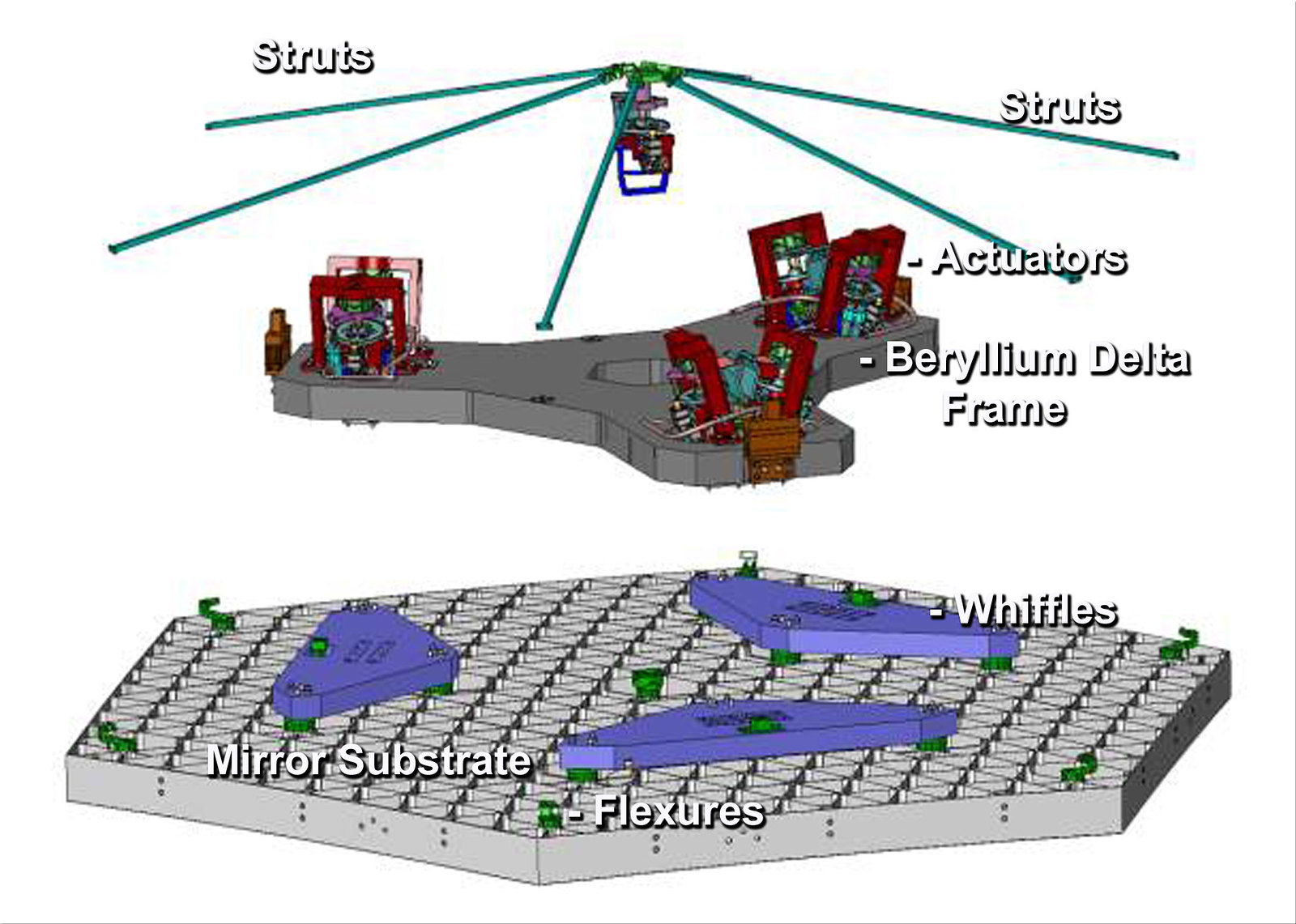

Once in space, getting these mirrors to focus correctly on faraway galaxies is another challenge. Actuators, or tiny mechanical motors, provide the answer to achieving a single perfect focus. The primary mirror segments and secondary mirror are moved by six actuators that are attached to the back of each mirror piece. The primary mirror segments also have an additional actuator at its center that adjusts its curvature. The telescope's tertiary mirror remains stationary.

Lee Feinberg, Webb Optical Telescope Element Manager at NASA Goddard explains, "Aligning the primary mirror segments as though they are a single large mirror means each mirror is aligned to 1/10,000th the thickness of a human hair. What's even more amazing is that the engineers and scientists working on the Webb telescope literally had to invent how to do this."

Engineering Challenge: Keeping Webb's Mirrors Cold

One further challenge is to keep Webb's mirror cold. To see the first stars and galaxies in the early Universe, astronomers have to observe the infrared light given off by them, and use a telescope and instruments optimized for this light. Because warm objects give off infrared light, or heat, if Webb's mirror was the same temperature as the Hubble Space Telescope's, the faint infrared light from distant galaxies would be lost in the infrared glow of the mirror. Thus, Webb needs to be very cold ("cryogenic"), with its mirrors at around -220 degrees C (-364 degree F). The mirror as a whole must be able to withstand very cold temperatures as well as hold its shape.

To keep Webb cold, it was sent into deep space, far from the Earth. Sunshields shade the mirrors and instruments from the Sun's heat, as well as keep them separated from the warm spacecraft bus.

In Depth:

Mirror Research & Innovation

NASA set out to research new ways to build mirrors for telescopes. The Advanced Mirror System Demonstrator (AMSD) program was a four-year partnership between NASA, the National Reconnaissance Office and the US Air Force to study ways to build lightweight mirrors. Based on the ASMD studies, two test mirrors were built and fully tested. One was made from beryllium by Ball Aerospace; the other was built by Kodak (formerly ITT, now the Harris Corporation) and was made from a special type of glass.

A team of experts was chosen to test both of these mirrors, to determine how well they worked, how much they cost, and how easy (or difficult) it would be to build a full-size, 6.5-meter mirror. The experts recommended that the beryllium mirror be selected for the James Webb Space Telescope, for several reasons, one being that beryllium holds its shape at cryogenic temperatures. Based on the expert team's recommendation, Northrop Grumman (the company that led the effort to build Webb) selected a beryllium mirror, and the project management at NASA Goddard approved this decision.

Why Beryllium?

Beryllium is a light metal (atomic symbol: Be) that has many features that make it desirable for Webb's primary mirror. In particular, beryllium is very strong for its weight and is good at holding its shape across a range of temperatures. Beryllium is a good conductor of electricity and heat, and is not magnetic.

Because it is light and strong, beryllium is often used to build parts for supersonic (faster-than-the-speed-of-sound) airplanes and the Space Shuttle. It is also used in more down-to-Earth applications like springs and tools. Special care has to be taken when working with beryllium, because it is unhealthy to breathe in or swallow beryllium dust.

How And Where The Beryllium Mirrors Were Made

The James Webb Space Telescope's 18 special lightweight beryllium mirrors made 14 stops to 11 different places around the U.S. to complete their manufacturing. They came to life at beryllium mines in Utah, and then moved across the country for processing and polishing. In fact, the mirrors made stops in eight states along the way, visiting some states more than once, before they journeyed to South America for lift-off and the beginning of their final journey to space. Download a four page flyer showing the journey of the mirrors.

The beryllium to make Webb's mirror was mined in Utah and purified at Brush Wellman in Ohio. The particular type of beryllium used in the Webb mirrors is called O-30 and is a fine powder. The powder was placed into a stainless steel canister and pressed into a flat shape. Once the steel canister was removed, the resulting chunk of beryllium was cut in half to make two mirror blanks about 1.3 meters (4 feet) across. Each mirror blank was used to make one mirror segment; the full mirror is made from 18 hexagonal segments.

Once the mirror blanks passed inspection, they were sent to Axsys Technologies in Cullman, Alabama. The first two mirror blanks were completed in March 2004.

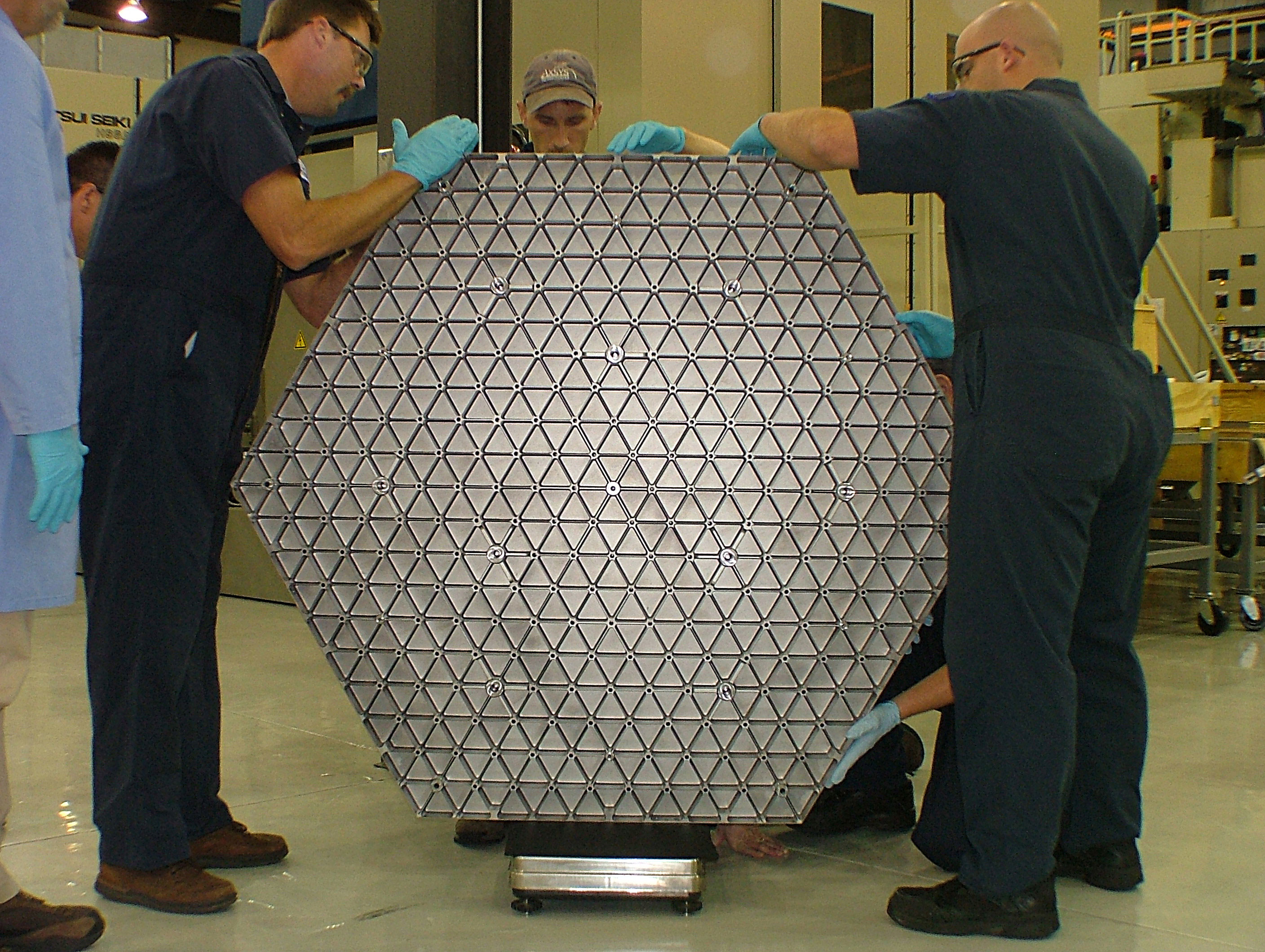

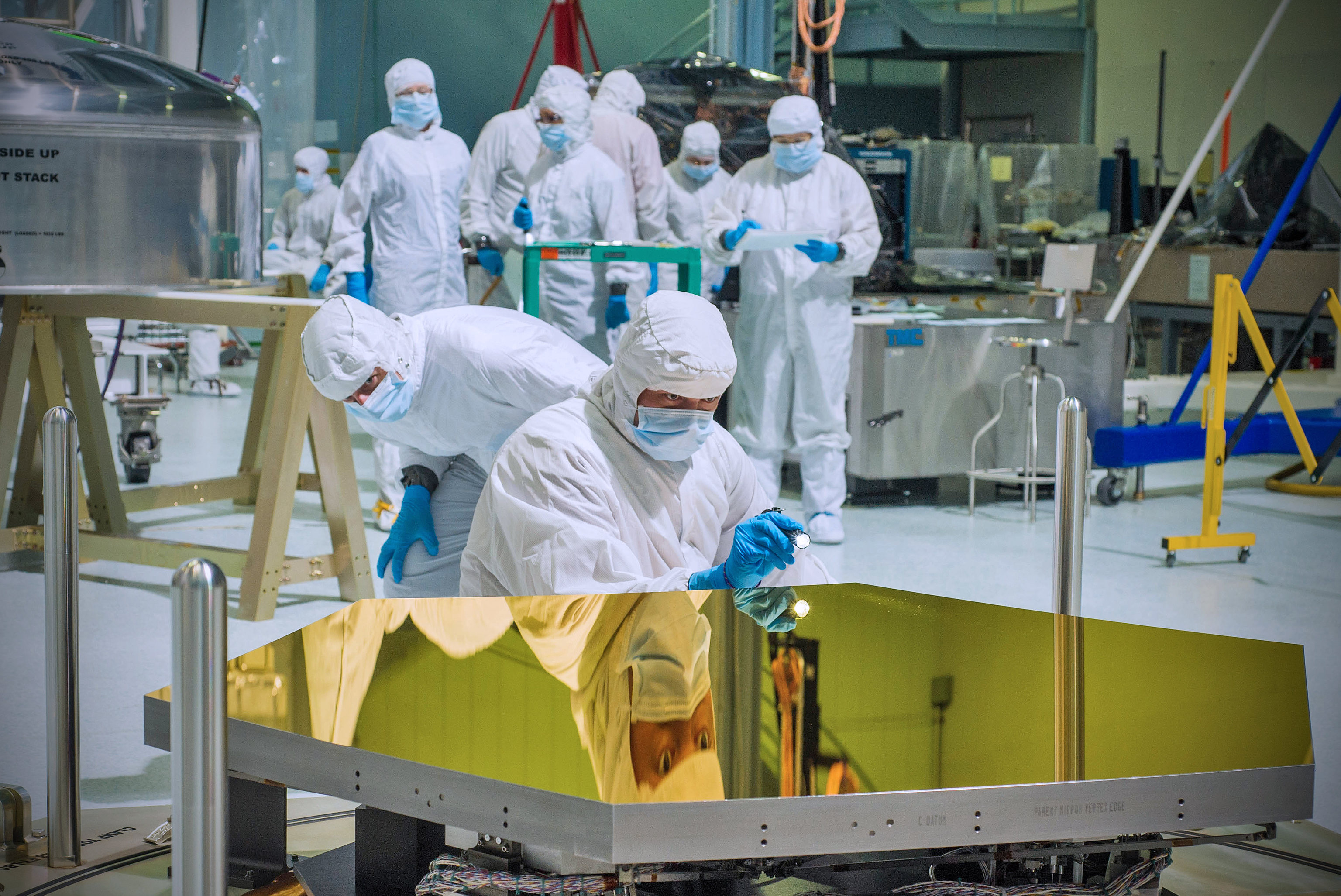

Axsys Technologies shaped the mirror blanks into their final shape. The process of shaping the mirror starts with cutting away most of the back side of the beryllium mirror blank, leaving just a thin "rib" structure. The ribs are only about 1 millimeter (about 1/25 of an inch) thick. Although most of the metal is gone, the ribs are enough to keep the segment's shape steady. This makes each segment very light. A beryllium mirror segment is 20 kilograms in mass. (A full primary mirror segment assembly including its actuator is about 40 kg.)

Mirror Polishing

Once the mirror segments were shaped by Axsys, they were sent to Richmond, CA, where SSG/Tinsley polished them.

SSG/Tinsley started by grinding down the surface of each mirror close to its final shape. After this was done, the mirrors were carefully smoothed out and polished. The process of smoothing and polishing was repeated until each mirror segment was nearly perfect. At that point, the segments traveled to NASA's Marshall Space Flight Center in Huntsville (MSFC), Alabama for cryogenic testing.

Since many materials change shape when they change temperature, a test team from Ball Aerospace worked together with NASA engineers at Marshall’s X-ray and Cryogenic Facility (XRCF) to cool the mirror segments down to the temperature Webb is experiencing in deep space, -400 degrees Fahrenheit (-240 degrees Celsius).

Cryogenic testing of the primary mirror segments began in at Marshall's XRCF by Ball Aerospace in 2009.

The change in mirror segment shape due to the exposure to these cryogenic temperatures was recorded by Ball Aerospace Engineers using a laser interferometer. This information, together with the mirrors, traveled back to California for final surface polishing at Tinsley. The mirrors' final polish was completed in June of 2011.

Gold Coating

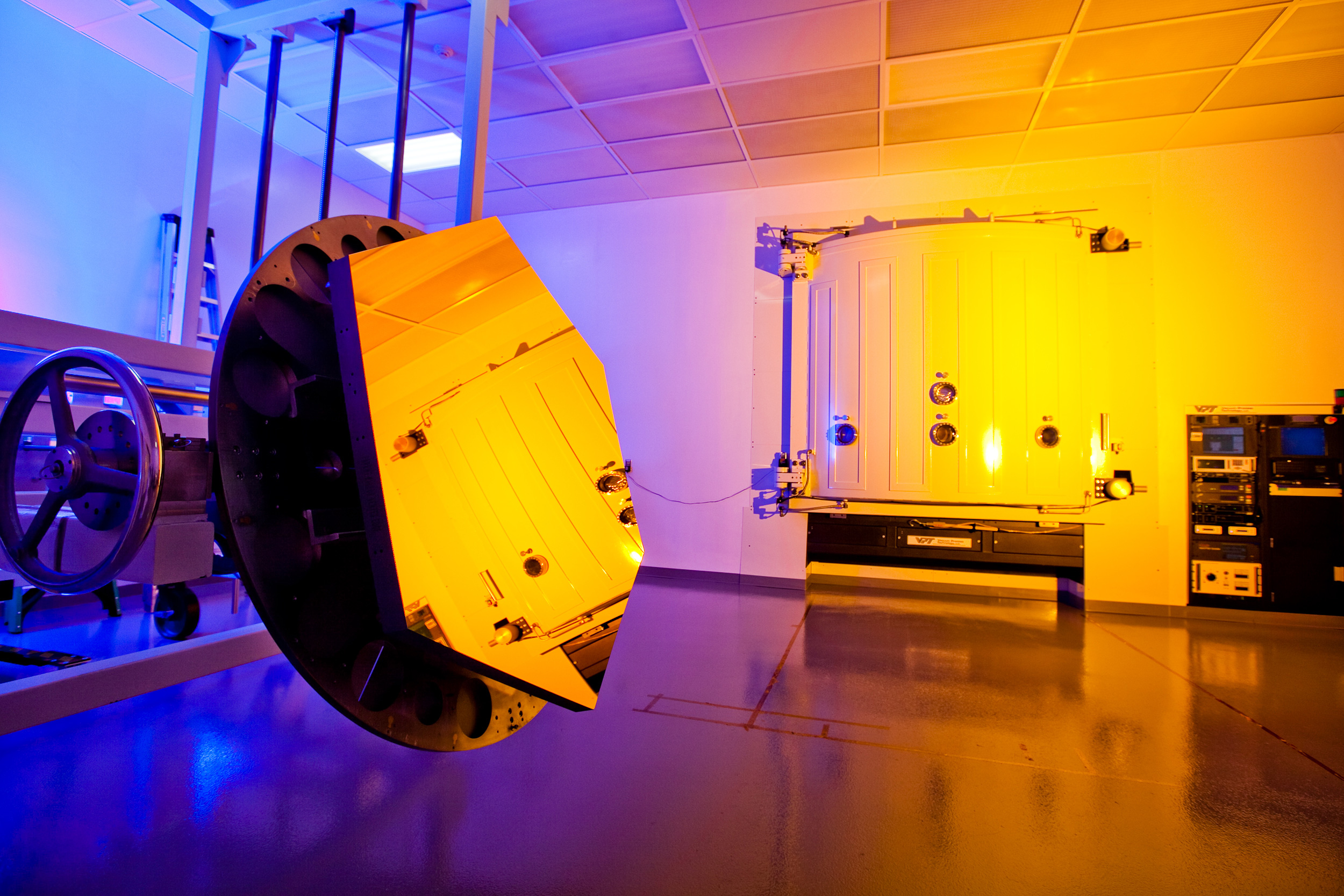

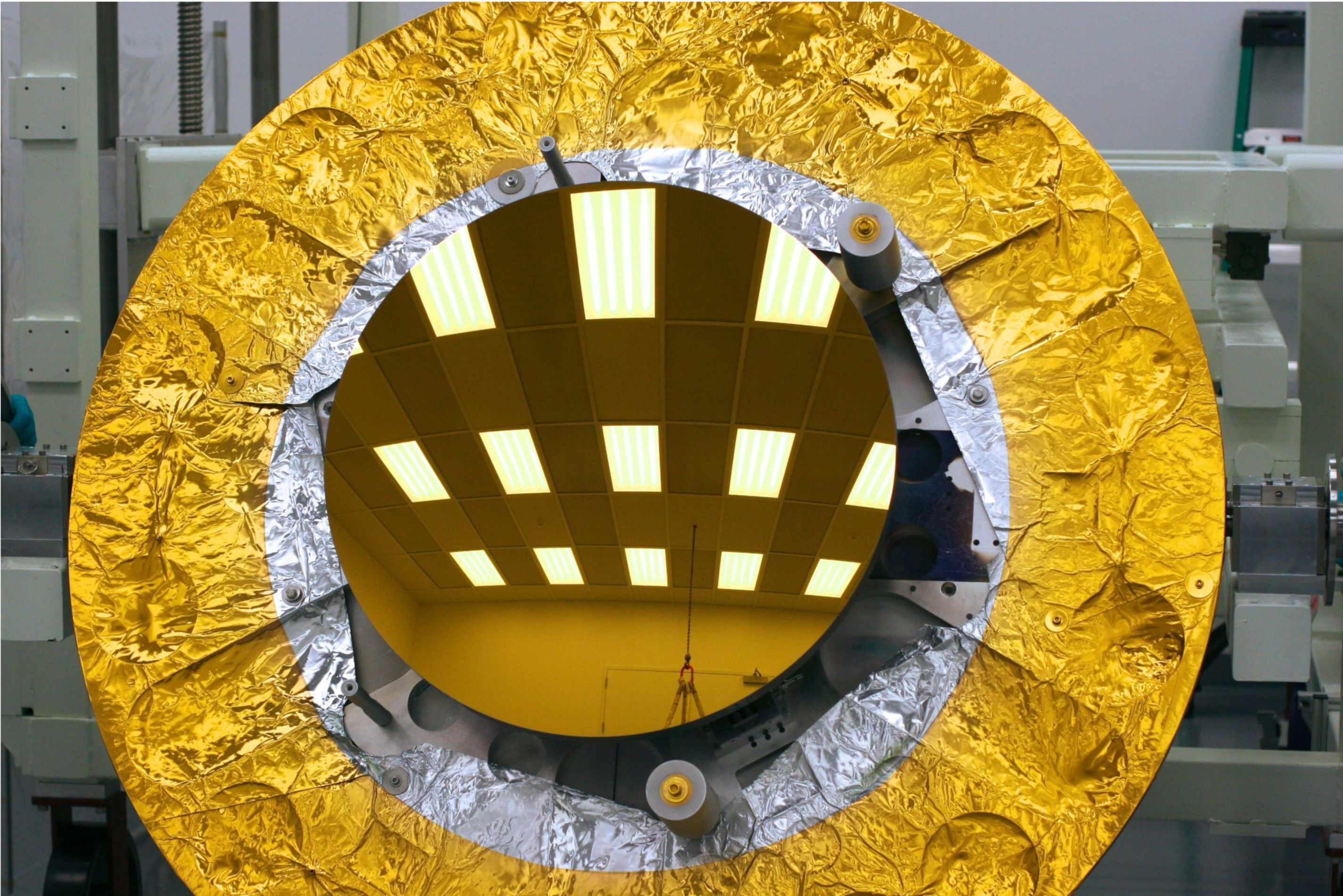

Once a mirror segment's final shape is corrected for any imaging effects due to cold temperatures, and polishing is complete, a thin coating of gold is applied. Gold improves the mirror's reflection of infrared light.

Some Technical Details: How is the gold applied to the mirrors? The answer is vacuum vapor deposition. Quantum Coating Incorporated did the coatings on our telescope mirrors. Essentially, the mirrors are put inside a vacuum chamber and a small quantity of gold is vaporized and it deposits on the mirror. Areas that we don't want coated (like the backside and all the mechanisms and such) are masked-off. Typical thickness of the gold is 1000 Angstroms (100 nanometers). A thin layer of amorphous SiO2 (glass) is deposited on top of the gold to protect it from scratches in case of handling or if particles get on the surface and move around (the gold is pure and very soft).

After the gold coating was applied, the mirrors once again traveled back to Marshall Space Flight Center for a final verification of mirror surface shape at cryogenic temperatures. The mirror segments were now complete. Next, they traveled to NASA's Goddard Space Flight Center in Greenbelt, Maryland.

The Assembled Mirrors

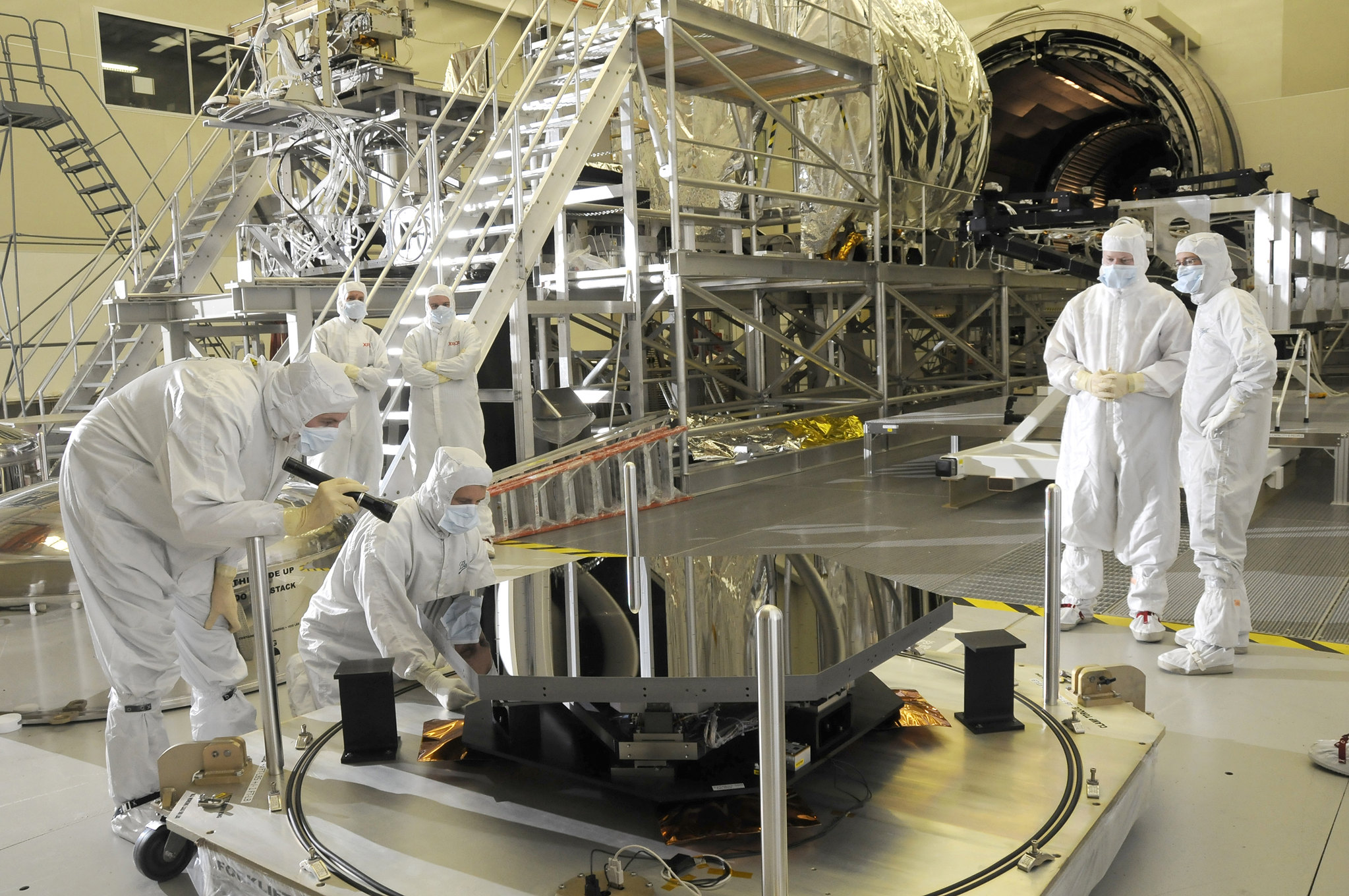

The first two flight mirrors arrived at NASA Goddard in September of 2012. By the end of 2013, all the flight primary mirror segments, as well as the secondary and tertiary mirrors would be at Goddard. The mirrors were stored in special protective canisters in the cleanroom, awaiting the arrival of the flight telescope structure.

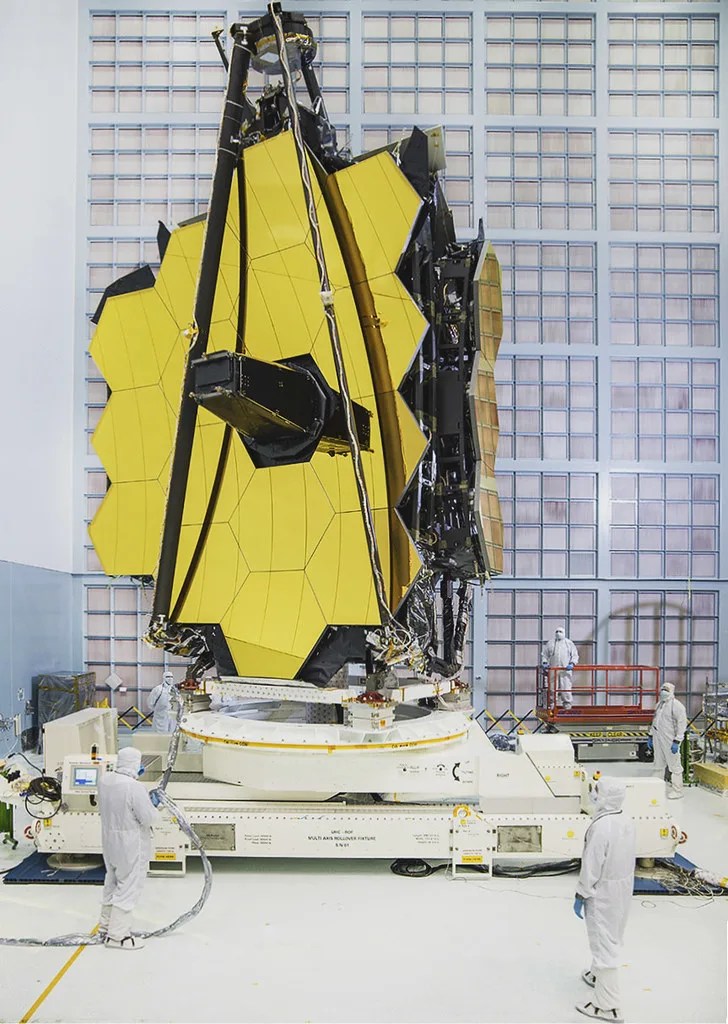

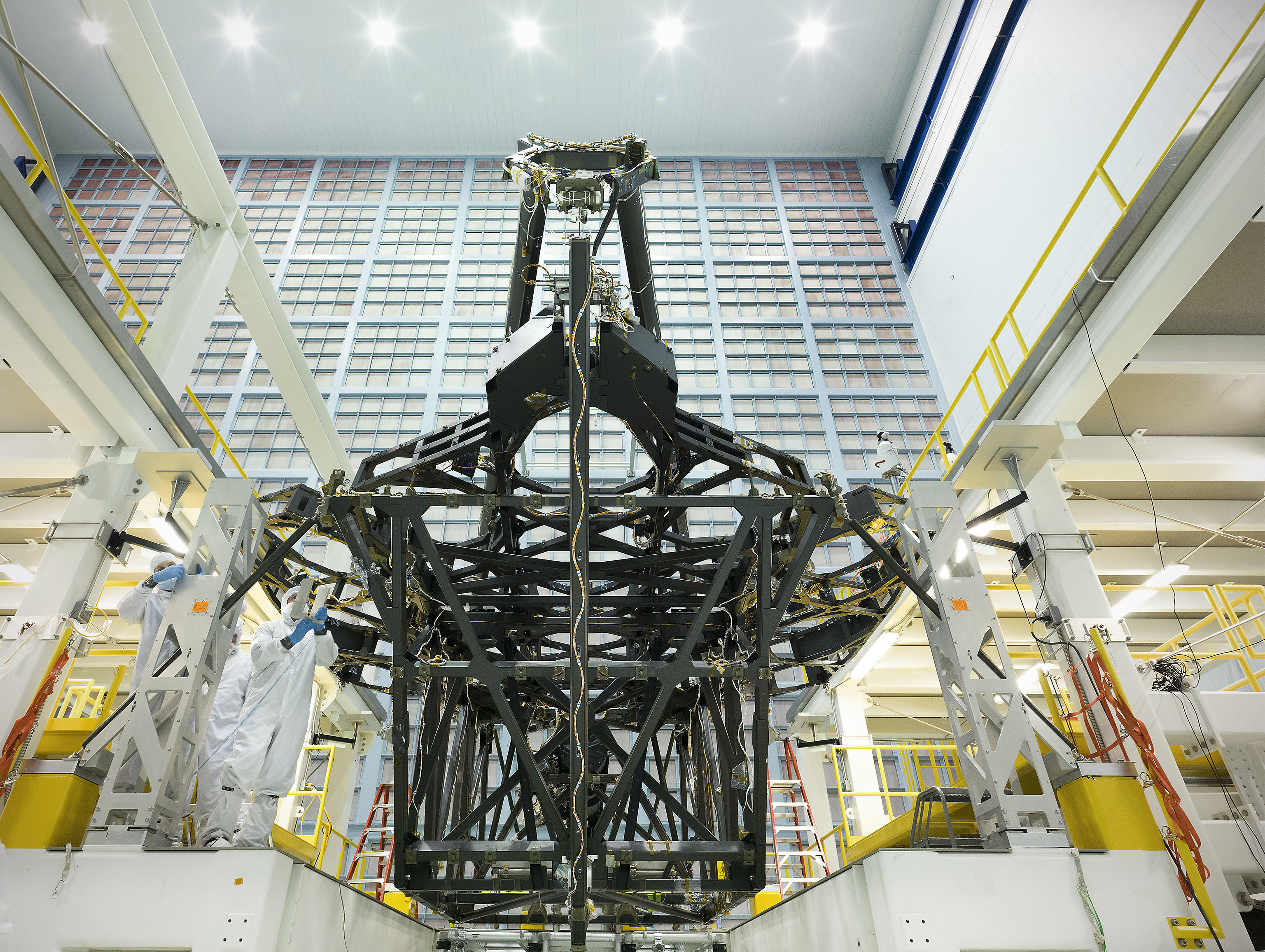

The flight telescope structure (essentially the bones of the telescope, which the mirrors would be mounted on) was shipped from Northrop Grumman, and arrived at NASA Goddard in August of 2015. It was moved to the assembly stand in November of 2015. On November 22, 2015, the first mirror was installed.

The last mirror was installed in February of 2016. Not long after, the protective covers were removed, and the full mirror was revealed.

The Uncovered Mirrors

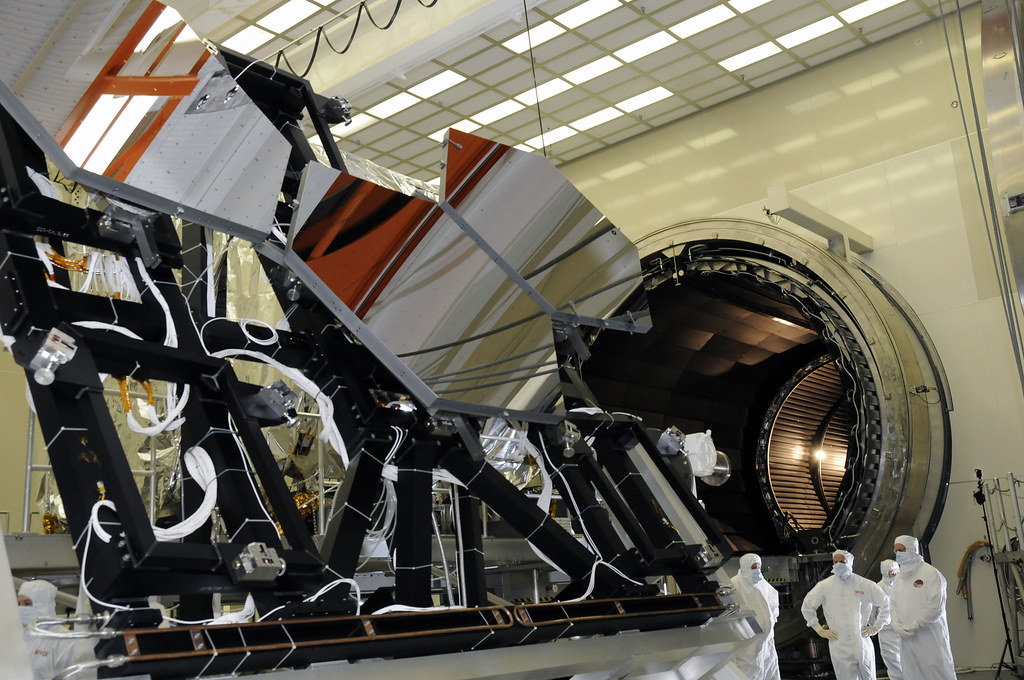

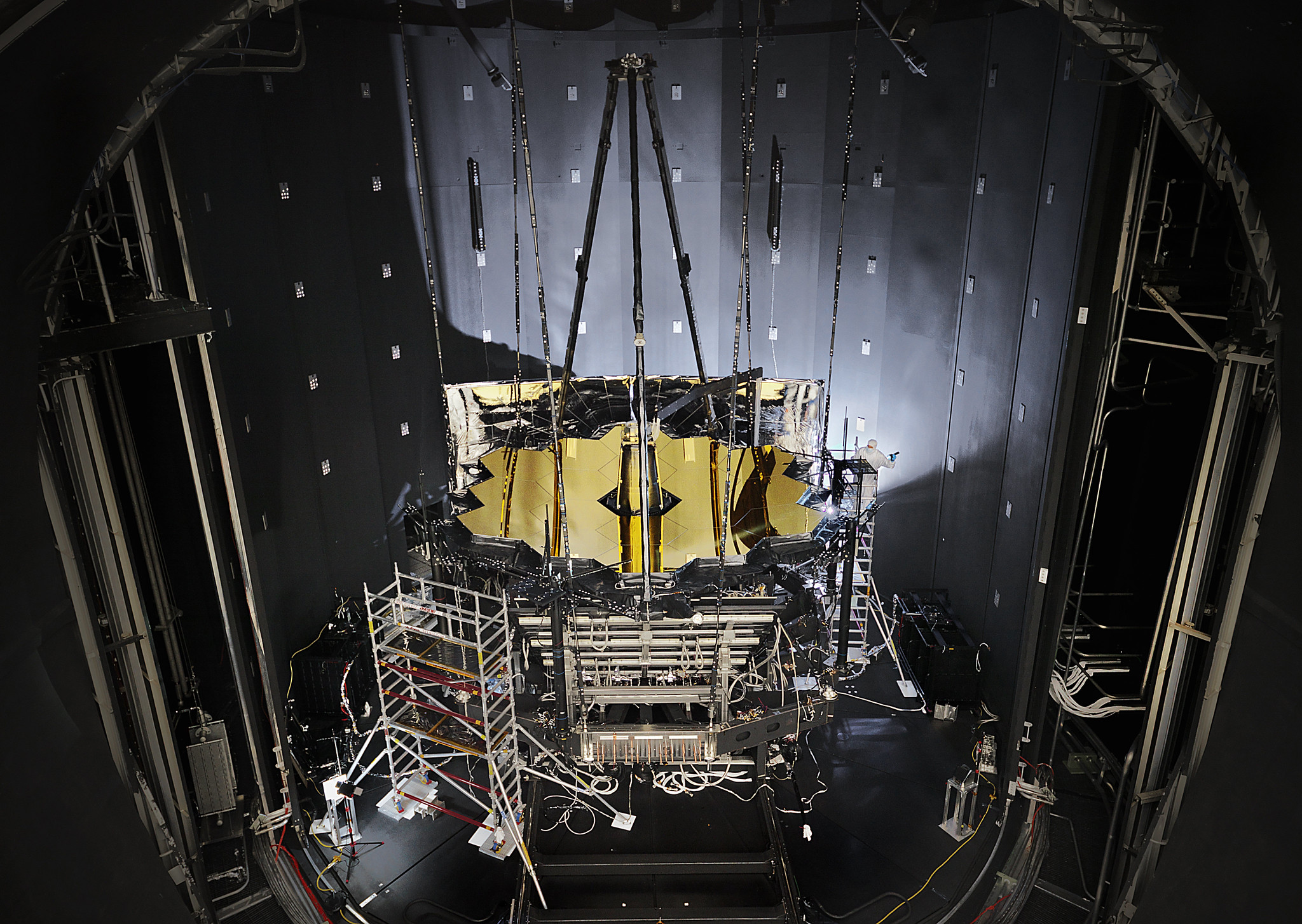

Once the mirrors were completed, the science instruments were integrated into the telescope. While at Goddard, the telescope also underwent environmental testing - both acoustic and vibration - to ensure it would be able to withstand the rigors of launch. That successfully completed, the telescope was sent off to NASA Johnson in Houston, Texas, for tests of the optics and instruments at cryogenic temperatures. NASA Johnson's Chamber A is the only thermal vacuum chamber NASA has that is large enough for Webb!

Aligning The Mirrors On Earth And In Space

Once the telescope reached orbit, engineers on Earth made adjustments/corrections to the positioning of the Webb telescope's primary mirror segments to bring them into alignment - to ensure they would produce sharp, focused images.

These corrections were made through a process called wavefront sensing and control, which aligns the mirrors to within tens of nanometers. During this process, a wavefront sensor (NIRCam in this case) measured any imperfections in the alignment of the mirror segments that prevented them from acting like a single, 6.5-meter (21.3-foot) mirror. Engineers used NIRCam to take 18 out-of-focus images of a star - one from each mirror segment. The engineers then used computer algorithms to determine the overall shape of the primary mirror from those individual images, and determined how they must move the mirrors to align them.

Engineers tested this alignment process in the cryogenic, vacuum environment of Chamber A at NASA's Johnson Space Center during about 100 days of cryogenic testing. The environment of the chamber simulates the frigid space environment where Webb operates, and where it collects data of never-before-observed portions of the universe. Inside the chamber, engineers fed laser light into and out of the telescope, acting like a source of artificial stars. The test verified the entire telescope, including its optics and instruments, worked correctly in this cold environment and ensured the telescope would work correctly in space.

Having passed its tests at NASA Johnson, Webb and its mirrors moved to Northrop Grumman, where the telescope was mated with the sunshield and spacecraft bus.

See Also

- Time-Lapse: Mirror Assembly

- Time-Lapse: Telescope Assembly

- Time-Lapse: Final Wing Test

- Photos: Flight Telescope

- Photos: Story of Webb

- Photos: Our Full Set of MIRROR Flickr Albums