PROJECT:

Deformable Mirror Technology development

SNAPSHOT

Deformable mirrors enable direct imaging of exoplanets by correcting imperfections or shape changes in a space telescope down to subatomic scales.

Credit: NASA Jet Propulsion Laboratory.

Finding and studying Earth-like planets orbiting nearby stars is critical to understand whether we are alone in the universe. To study such planets and assess if they can sustain life, it is necessary to directly image them. However, these planets are difficult to observe, since light from the host star hides them with its glare. A coronagraph instrument can be used to remove the glare light from the host star, enabling reflected light from the planet to be collected. A deformable mirror is an essential component of a coronagraph, as it can correct the tiniest of imperfections in the telescope and remove any remaining starlight contamination.

Detecting an Earth-like planet poses significant challenges as the planet is approximately 10 billion times fainter than its parent star. The main challenge is to block nearly all of the star's light so that the faint light reflected from the planet can be collected. A coronagraph can block the starlight, however, any instability in the telescope’s optics—such as misalignment between mirrors or a change in the mirror’s shape—can result in starlight leakage, causing glare that hides the planet. Therefore, detecting an Earth-like planet using a coronagraph requires precise control of both the telescope and the instrument’s optical quality, or wavefront, to an extraordinary level of 10s of picometers (pm), which is approximately on the order of the size of a hydrogen atom.

Deformable mirrors will enable future space coronagraphs to achieve this level of control. These devices will be demonstrated in space on a coronagraph technology demonstration instrument on NASA’s Roman Space Telescope, which will launch by May 2027. This technology will also be critical to enable a future flagship mission after Roman recommended by the 2020 Decadal Survey in Astronomy and Astrophysics, provisionally called the “Habitable Worlds Observatory” (HWO).

What is a deformable mirror and how do they work?

Deformable Mirrors (DM) are devices that can adjust the optical path of incoming light by changing the shape of a reflective mirror using precisely controlled piston-like actuators. By adjusting the shape of the mirror, it is possible to correct the wavefront that is perturbated by optical aberrations upstream and downstream of the DM. These aberrations can be caused by external perturbations, like atmospheric turbulence, or by optical misalignments or defects internal to the telescope.

DM technology originated to enable adaptive optics (AO) in ground-based telescopes, where the primary goal is to correct the aberrations caused by atmospheric turbulence. The main characteristics of a DM are: 1) the number of actuators, which is proportional to the correctable field of view; 2) the actuators’ maximum stroke – i.e., how far they can move; 3) the DM speed, or time required to modify the DM surface; 4) the surface height resolution that defines the smallest wavefront control step, and (5) the stability of the DM surface.

Ground-based deformable mirrors have set the state-of-the-art in performance, but to lay the groundwork to eventually achieve ambitious goals like the Habitable Worlds Observatory, further development of DMs for use in space is underway.

For a space telescope, DMs do not need to correct for the atmosphere, but instead must correct the very small optical perturbations that slowly occur as the space telescope and instrument heat up and cool down in orbit. Contrast goals (the brightness difference between the planet and the star) for DMs in space are on the order of 10-10 which is 1000 times deeper than the contrast goals of ground-based counterparts. For space applications total stroke requirements are usually less than a micrometer; however, DM surface height resolution of ~10 pm and DM surface stability of ~10 pm/hour are the key and driving requirements.

Another key aspect is the increased number of actuators needed for both space- and ground-based applications. Each actuator requires a high voltage connection (on the order of 100V) and fabricating a large number of connections creates an additional challenge.

Deformable Mirror State-of-the-Art

Two main DM actuator technologies are currently being considered for space missions. The first is electrostrictive technology, in which an actuator is mechanically connected to the DM’s reflective surface. When a voltage is applied to the actuator, it contracts and modifies the mirror surface. The second technology is the electrostatically-forced Micro Electro-Mechanical System (MEMS) DM. In this case, the mirror surface is deformed by an electrostatic force between an electrode and the mirror.

Several NASA-sponsored contractor teams are working on advancing the DM performance required to meet the requirements of future NASA missions, which are much more stringent than most commercial applications, and thus, have a limited market application. Some examples of those efforts include improving the mirror’s surface quality or developing more advanced DM electronics.

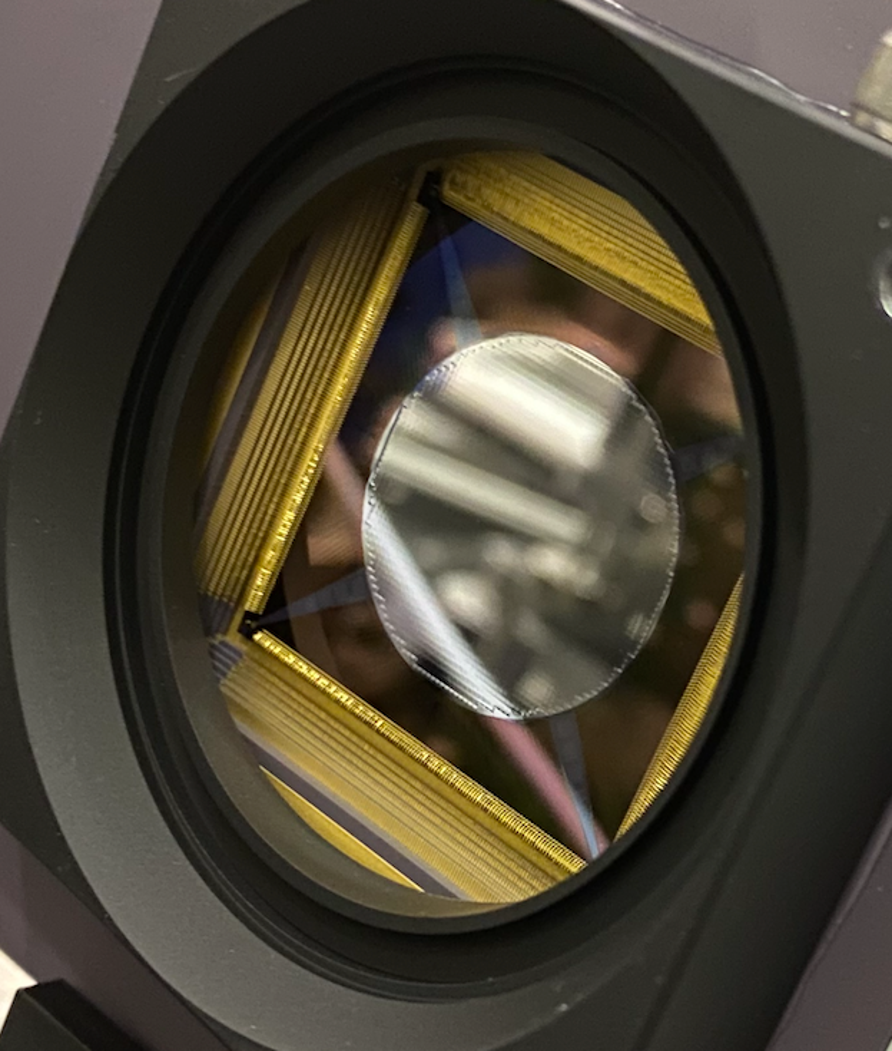

MEMS DMs manufactured by Boston Micromachines Corporation (BMC) have been tested in vacuum conditions and have undergone launch vibration testing. The largest space-qualified BMC device is the 2k DM (shown in Fig. 2), which has 50 actuators across its diameter (2040 actuators in total). Each actuator is only 400 microns across. The largest MEMS DM produced by BMC is the 4k DM, which has 64 actuators across its diameter (4096 actuators in total) and is used in the coronagraph instrument for the Gemini ground-based observatory. However, the 4k DM has not been qualified for space flight.

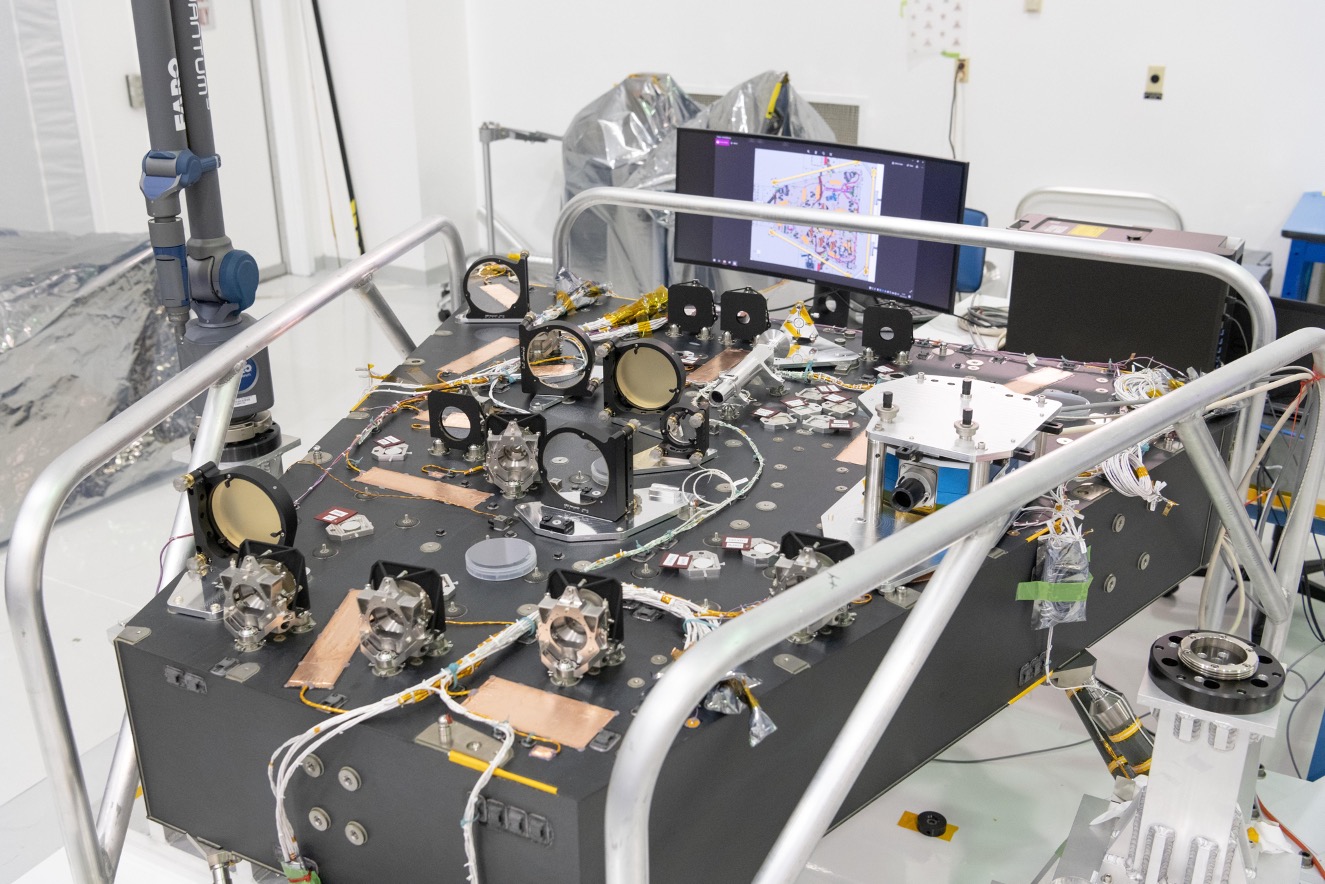

Electrostrictive DMs manufactured by AOA Xinetics (AOX) have also been validated in vacuum and qualified for space flight. The AOX 2k DM has a 48 x 48 actuator grid (2304 actuators) with a 1 mm pitch. Two of these AOX 2k DMs will be used in the Roman Space Telescope Coronagraph (Fig. 3) to demonstrate the DM technology for high-contrast imaging in space. AOX has also manufactured larger devices, including a 64 x 64 actuator unit tested at JPL.

Preparing the technology for the Habitable Worlds Observatory

Deformable Mirror technology has advanced rapidly, and a version of this technology will be demonstrated in space on the Roman Space Telescope. However, it is anticipated that for wavefront control for missions like the HWO, even larger DMs with up to ~10,000 actuators would be required, such as 96 x 96 arrays. Providing a high-voltage connection to each of the actuators is a challenge that will require a new design.

The HWO would also involve unprecedented wavefront control requirements, such as a resolution step size down to single-digit picometers, and a stability of ~10 pm/hr. These requirements will not only drive the DM design, but also the electronics that control the DMs, since the resolution and stability are largely defined by the command signals sent by the controller, which require the implementation of filters to remove any noise the electronics could introduce.

NASA’s Astrophysics Division investments in DM technologies have advanced DMs for space flight onboard the Roman Space Telescope Coronagraph, and the Division is preparing a Technology Roadmap to further advance the DM performance to enable the HWO.

Author: Eduardo Bendek, Ph.D. Jet Propulsion Laboratory, California Institute of Technology.

The research was carried out at the Jet Propulsion Laboratory, California Institute of Technology, under a contract with the National Aeronautics and Space Administration (80NM0018D0004).

ACTIVITY LEADS

Dr. Eduardo Bendek (JPL) and Dr. Tyler Groff (GSFC), Co-chairs of DM Technology Roadmap working group; Paul Bierden (BMC); Kevin King (AOX).

SPONSORING ORGANIZATION

Astrophysics Division Strategic Astrophysics Technology (SAT) Program, and the NASA Small Business Innovation Research (SBIR) Program